ROTARY ASPHALT CUTTERS

Asphalt repair projects are made easy with the CUT-R-TACH rotary asphalt cutting attachments that increase the utilization rates of existing fleet equipment. Specific models mount quickly to

popular prime mover vehicles, including: wheel loaders, excavators, motor graders and backhoes. Produce smooth sized cuts in asphalt up to 6000 linear feet per hour and up to 5-1/2 inch deep in

asphalt and asphaltic concrete materials. The patented clamping system mounts securely.

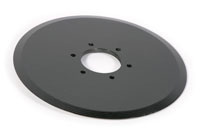

130C CLAMP MOUNT CUT-R-TACH

Bucket Mount, 13-1/2 inch diameter blade, 5 inches maximum cutting depth. Twin Oilite- type, sleeve bearings, 25,000 lbs maximum down force capacity. Not for use with skid loaders. Produces smooth

sided cuts up to 5-1/2 inches deep at rates up to 6000 feet per hour through high density asphaltic materials. Patented clamping system. Built with steel plate structures to resist stress related

cracking and distortion. Special alloy-steel cutting blades are field replaceable without disturbing bearing or seals. No special tools required for installation. Attach to most backhoes,

tractor/wheel loaders, road graders, dozers and other construction machinery.

-

Blade Diameter: 13-1/2 inch

-

Maximum Cutting depth: 5 inches

-

Oilite-type sleeve bearing

-

Maximum down force capacity: 25,000 lbs

190C CLAMP MOUNT CUT-R-TACH

190C Clamp Mount CUT-R-TACH Rotary Asphalt Cutting Attachment Bucket Mount, 19 inch diameter blade, 5-1/2 inches maximum cutting depth. Twin Timken- type, tapered roller bearings, 50,000 lbs

maximum down force capacity. Not for use with skid loaders. Produces smooth sided cuts up to 5-1/2 inches deep at rates up to 6000 feet per hour through high density asphaltic materials. Patented

clamping system. Built with steel plate structures to resist stress related cracking and distortion. Special alloy-steel cutting blades are field replaceable without disturbing bearing or seals. No

special tools required for installation. Attach to most backhoes, tractor/wheel loaders, road graders, dozers and other construction machinery.

-

Blade Diameter: 19 inch

-

Maximum Cutting depth: 5-1/2 inches

-

Timkin̨̉ Type bearing

-

Maximum down force capacity: 50,000 lbs

190M MOLDBOARD MOUNT CUT-R-TACH

Moldboard Mount, 19 inch diameter blade, 5- 1/2 inches maximum cutting depth. Twin Timken-type, tapered roller bearings, 50,000 lbs maximum down force capacity. Fixed and vertical adjustable jaws

clamp to moldboards 13 to 28 inches in height. 13 inches minimum moldboard lift required. Produces smooth sided cuts up to 5-1/2 inches deep at rates up to 6000 feet per hour through high density

asphaltic materials. Patented clamping system. Built with steel plate structures to resist stress related cracking and distortion. Special alloy-steel cutting blades are field replaceable without

disturbing bearing or seals. No special tools required for installation. Attach to most backhoes, tractor/wheel loaders, road graders, dozers and other construction machinery.

-

Blade Diameter: 19 inch

-

Maximum Cutting depth: 5-1/2 inches

-

Timkin Type bearing

-

Maximum down force capacity: 50,000 lbs

-

13-18 inch heigh adjustment, 13 minimum

Download (PDF) File

130 and 190 Series Asphalt Cutters (CUT-R-TACH) Operator Manual

130C CLAMP MOUNT CUT-R-TACH

Bucket Mount, 13-1/2 inch diameter blade, 5 inches maximum cutting depth. Twin Oilite- type, sleeve bearings, 25,000 lbs maximum down force capacity. Not for use with

skid loaders. Produces smooth sided cuts up to 5-1/2 inches deep at rates up to 6000 feet per hour through high density asphaltic materials. Patented clamping system. Built with steel plate

structures to resist stress related cracking and distortion. Special alloy-steel cutting blades are field replaceable without disturbing bearing or seals. No special tools required for

installation. Attach to most backhoes, tractor/wheel loaders, road graders, dozers and other construction machinery.

-

Blade Diameter: 13-1/2 inch

-

Maximum Cutting depth: 5 inches

-

Oilite-type sleeve bearing

-

Maximum down force capacity: 25,000 lbs

Specifications:

FRAME: Utilized welded steel plate

CUTTING BLADE: 13-1/2 inch (343 MM) diameter

HUB ASSEMBLY: Alloy steel axle with steel hub integral to blade

BEARINGS: Sleeve type

MOUNTING: Twin screw pivoting clamp

CUTTING DEPTH: 5 inch (127 mm)

190C CLAMP MOUNT CUT-R-TACH

190C Clamp Mount CUT-R-TACH® Rotary Asphalt Cutting Attachment Bucket Mount, 19 inch diameter blade, 5-1/2 inches maximum cutting depth. Twin Timken - type, tapered roller bearings, 50,000 lbs

maximum down force capacity. Not for use with skid loaders. Produces smooth sided cuts up to 5-1/2 inches deep at rates up to 6000 feet per hour through high density asphaltic materials. Patented

clamping system. Built with steel plate structures to resist stress related cracking and distortion. Special alloy-steel cutting blades are field replaceable without disturbing bearing or seals. No

special tools required for installation. Attach to most backhoes, tractor/wheel loaders, road graders, dozers and other construction machinery.

-

Blade Diameter: 19 inch

-

Maximum Cutting depth: 5-1/2 inches

-

Timkin® Type bearing

-

Maximum down force capacity: 50,000 lbs

Specifications:

FRAME: Utilized welded steel plate

CUTTING BLADE: 19 inch (483 MM) diameter

HUB ASSEMBLY: Alloy steel axle with steel hub integral to blade

BEARINGS: Timkin® Type

MOUNTING: Twin screw pivoting clamp

CUTTING DEPTH: 5-1/2 inch (140 mm)

190M MOLDBOARD MOUNT CUT-R-TACH

Moldboard Mount, 19 inch diameter blade, 5- 1/2 inches maximum cutting depth. Twin Timken-type, tapered roller bearings, 50,000 lbs maximum down force capacity. Fixed and vertical adjustable jaws

clamp to moldboards 13 to 28 inches in height. 13 inches minimum moldboard lift required. Produces smooth sided cuts up to 5-1/2 inches deep at rates up to 6000 feet per hour through high density

asphaltic materials. Patented clamping system. Built with steel plate structures to resist stress related cracking and distortion. Special alloy-steel cutting blades are field replaceable without

disturbing bearing or seals. No special tools required for installation. Attach to most backhoes, tractor/wheel loaders, road graders, dozers and other construction machinery.

-

Blade Diameter: 19 inch

-

Maximum Cutting depth: 5-1/2 inches

-

Timkin® Type bearing

-

Maximum down force capacity: 50,000 lbs

-

13-18 inch heigh adjustment, 13 minimum

Specifications:

FRAME: Utilized welded steel plate

CUTTING BLADE: 19 inch (483 MM) diameter

HUB ASSEMBLY: Alloy steel axle with steel hub integral to blade

BEARINGS: Timkin® Type

MOUNTING: Fixed and adjustable jaws to moldboard 13 inch (330 mm) to 28 inch (711 mm) in height. Minimun moldboard lift required: 13 inch (3330 mm)

CUTTING DEPTH: 5-1/2 inch (140 mm)