Click here to download Instruction Manual

Click here to download Curb Mix Info

Click here to download Choosing Auger Size Chart

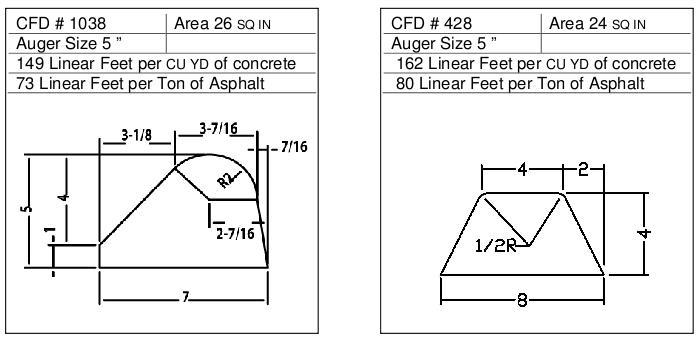

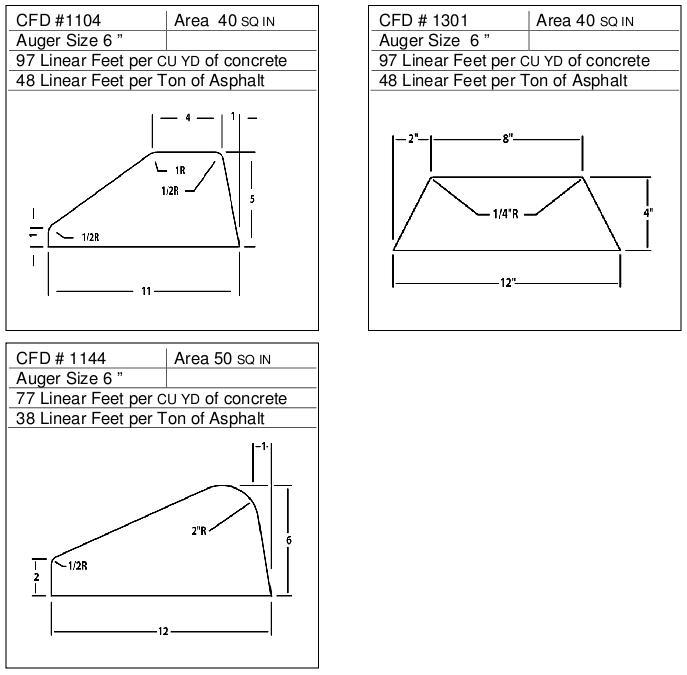

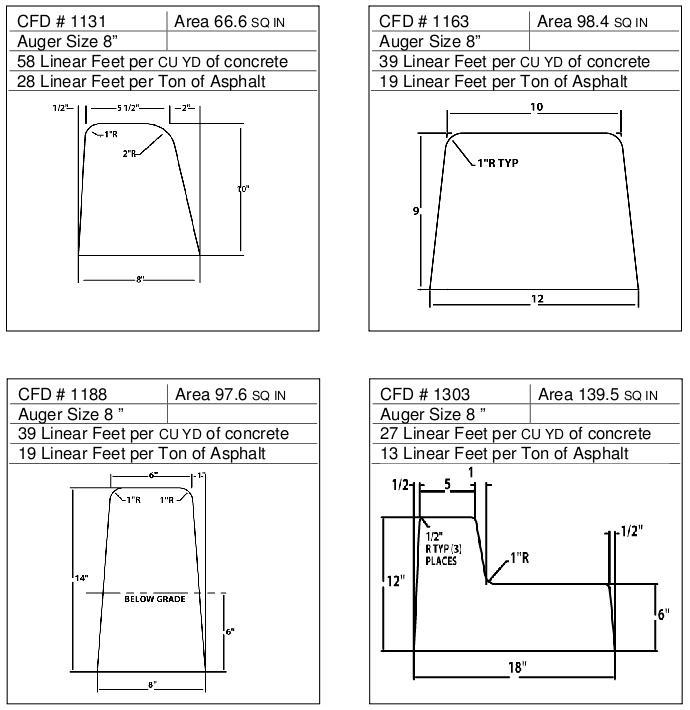

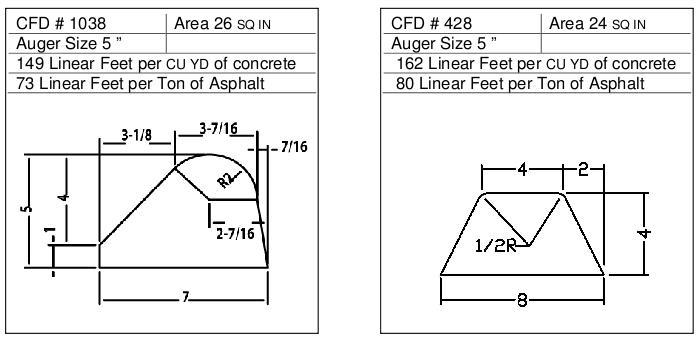

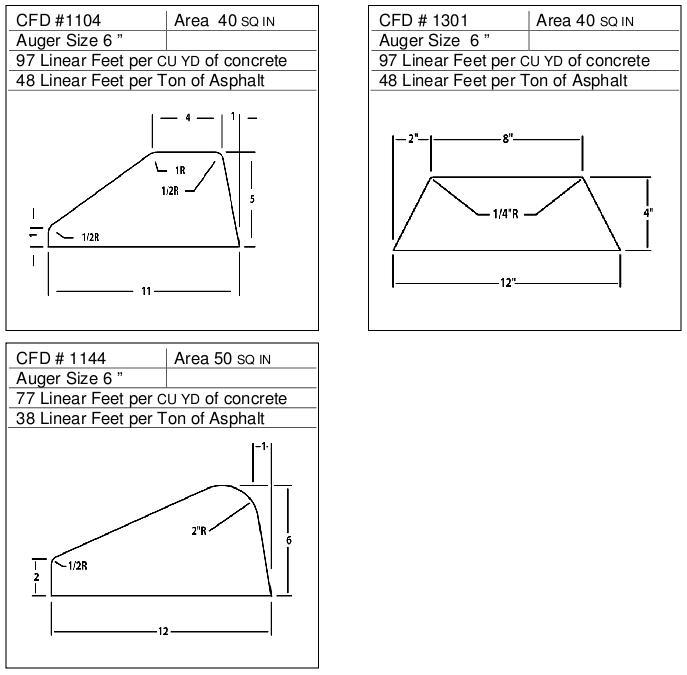

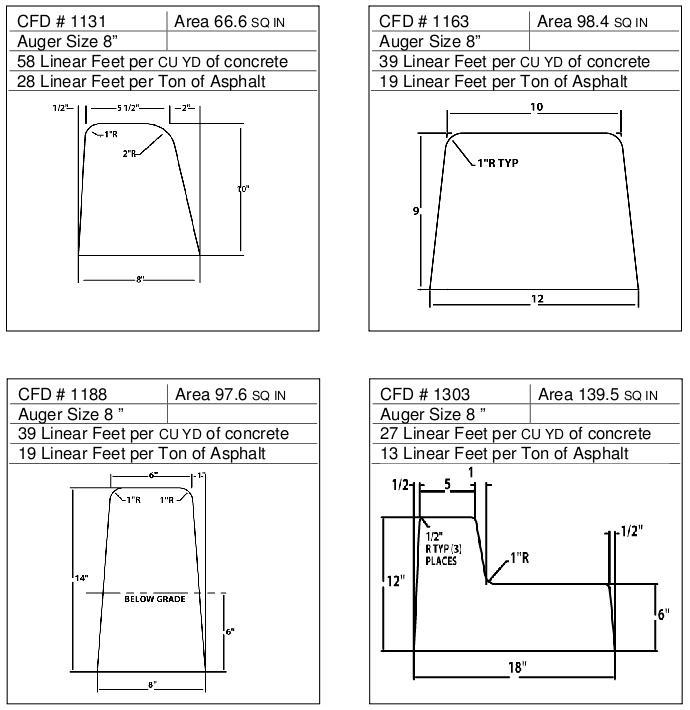

Click here to download CFD for 5 inch Auger

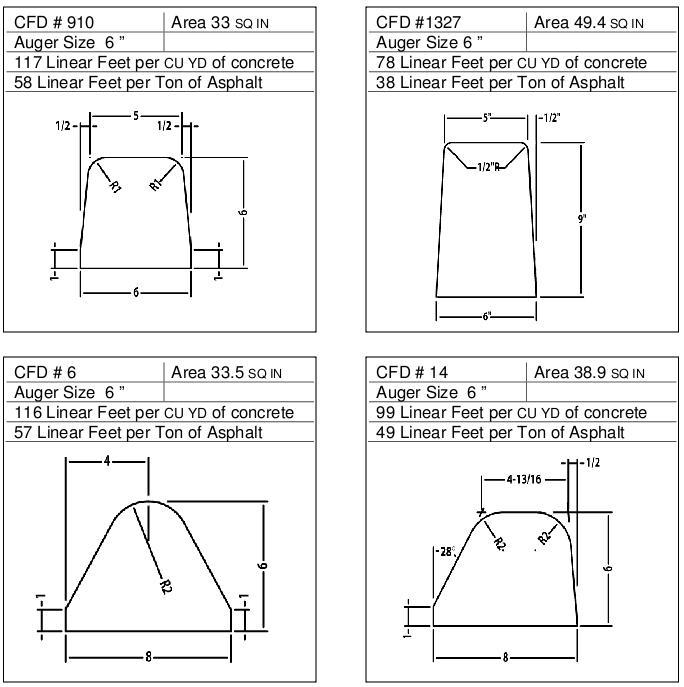

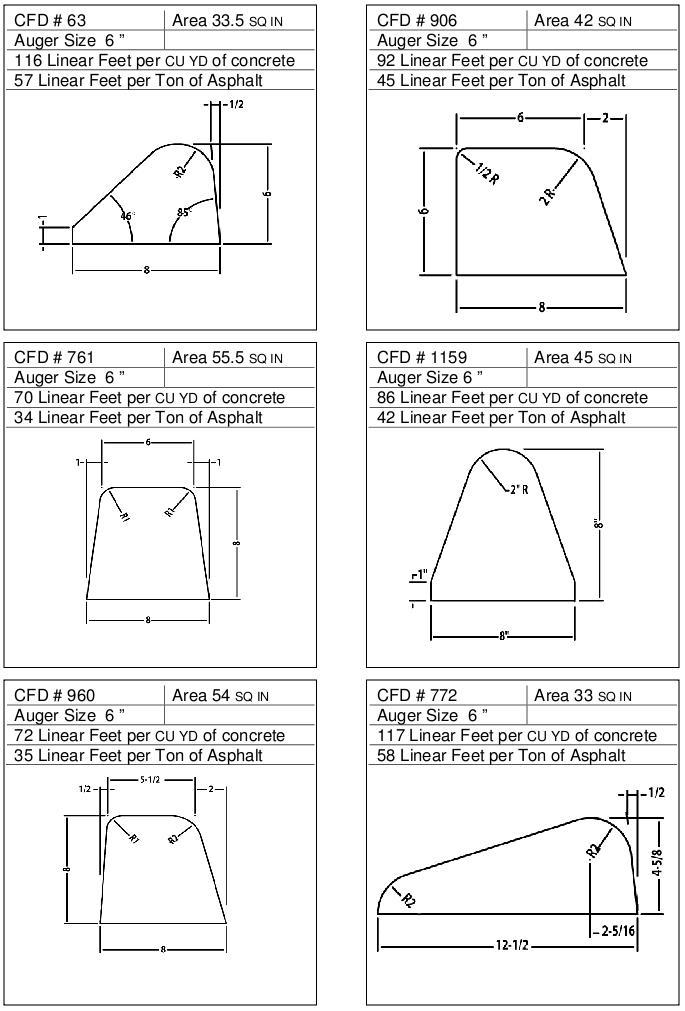

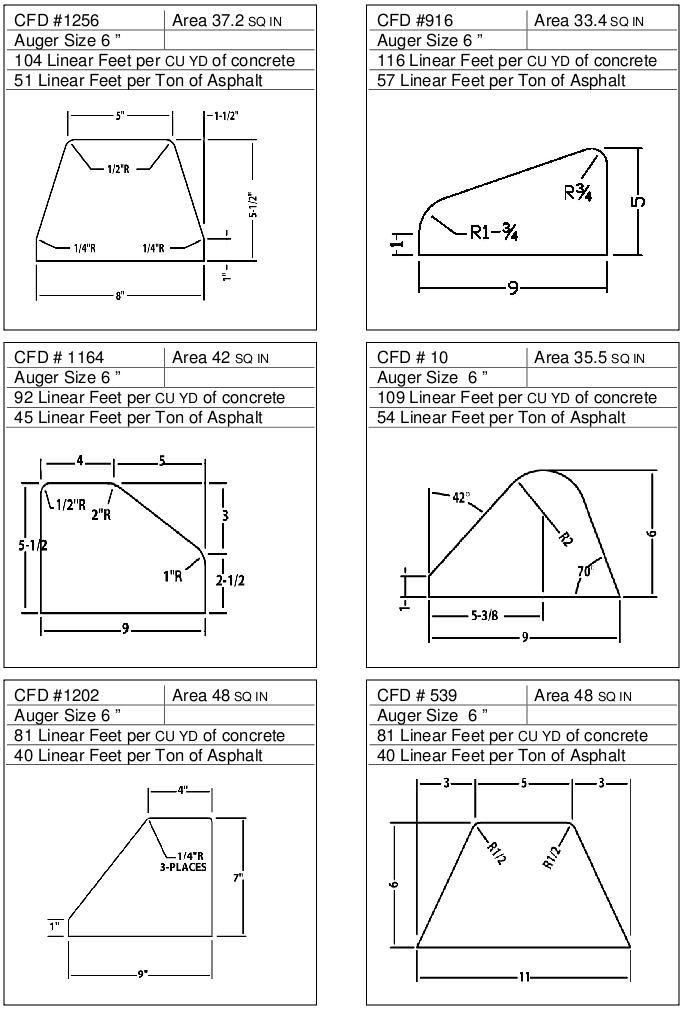

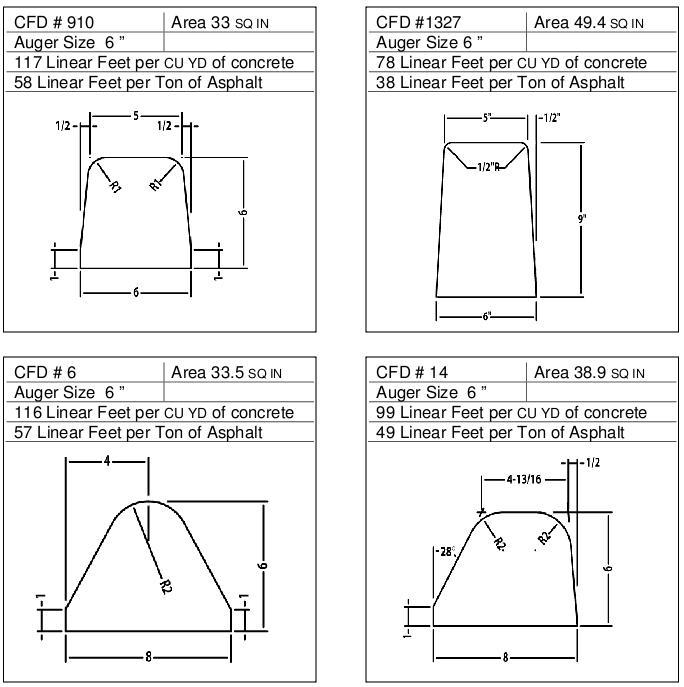

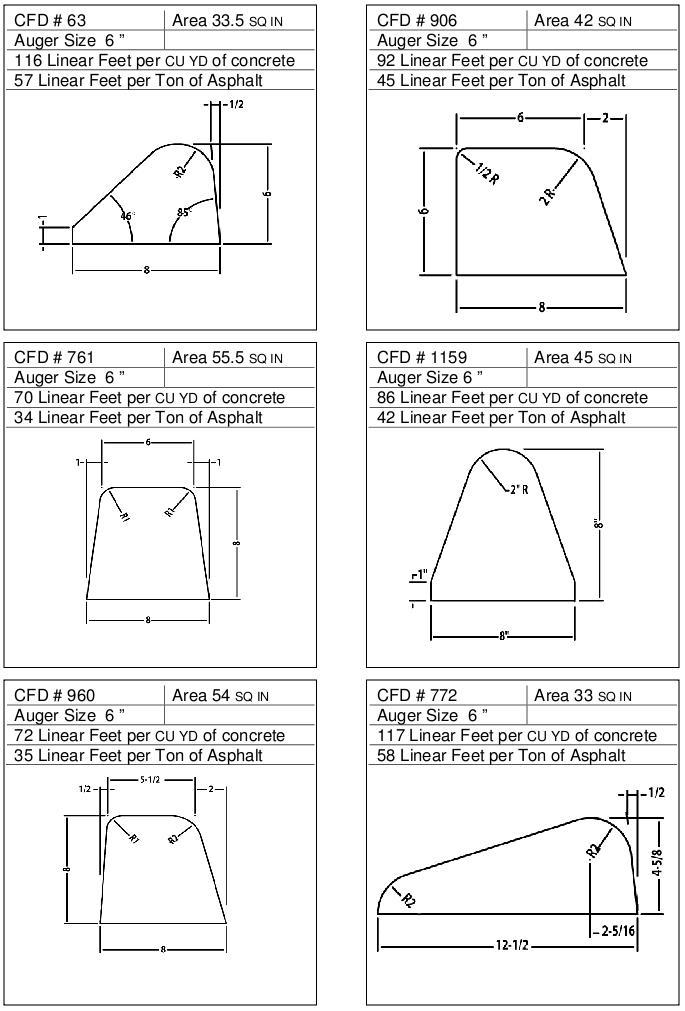

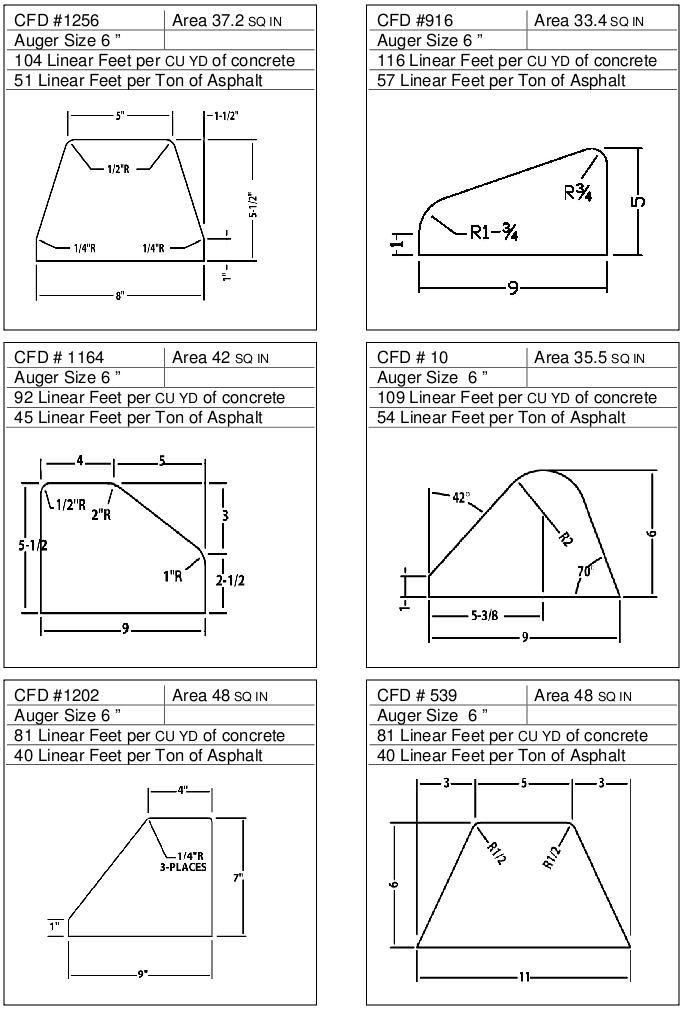

Click here to download CFD for 6 inch Auger

Click here to download CFD for 8 inch Auger

Commercial Curbilders

PRODUCT OVERVIEW

For over fifty years the Miller MC Series Curbilders have offered unequaled performance and versatility for the placement of free- standing curb. These simple and efficient self-propelled machines

operate on the extrusion principle and provide the most economical means available of constructing small to mid-sized continuous curb from either concrete or asphalt. This quick and efficient

process drastically reduces the high labor costs associated with hand formed and poured curb and produces high quality, extremely dense curb at a rate of up to 15 fpm (up to 30 fpm for MC900).

Millerâs exclusive interchangeable extrusion auger assemblies give each Curbilder the capacity to extrude more shapes and sizes than any machine in its class, from 3-1/2â to 18â high curb. A wide

variety of options allow these machines to meet the toughest specification work.

-

05 - Curbilder product category

-

13 - horsepower of motor

-

HR - motor type, H for Honda, K for Kohler, second digit R for recoil, E for electric start

-

650 - series of Curbilder

-

06 - auger diameter

-

S - type of auger, S for solid, H for hollow

-

S - type of wheels, S for solid rubber, P for pneumatic

Miller Advantages

-

Every model will extrude

concrete or asphalt

-

Four interchangeable

extrusion assemblies with auger

-

diameters from 5â to

10â

-

Extrude from right or left

side of the machine

-

Place curb within 1â of

an obstacle

-

Extrude steel rod through

the curb center

-

(optional hollow auger

assembly)

-

Extrude over pins

(optional form)

-

Two-piece 5â and 6â cast

auger allowing four separate wear

-

surfaces for extended

life

-

Easy access and removal of

all extrusion components for

-

maintenance and quick

clean-up

-

Nearly 2,000 curb choices

with custom shapes available at no

-

additional cost

A high percentage of extruded

curbs have a cross sectional area between 33 and 55 square inches, so every Miller Curbilder is equipped with the 6â extrusion assembly as standard equipment.

Assemblies of other sizes are available and can easily be retrofitted to machines in the field. Each assembly is complete and

includes auger, auger shaft, auger housing, compaction tube, bearings and driven sprocket.

|

Machine Specifications

|

|

Models

|

MC550

|

MC650

|

MC850

|

MC900

|

|

Operating Weight

|

668 lb.

|

718 lb.

|

918 lb.

|

959 lb.

|

|

Height (Steering handle down)

|

38 inch

|

38 inch

|

40.5 inch

|

|

Width

|

32.25 inch

|

32.25 inch

|

32.25 inch

|

|

Length with Form (steering handle up)

|

77.5 inch

|

77.5 inch

|

91.5 inch

|

|

Wheelbase

|

52.75 inch

|

52.75 inch

|

71 inch

|

|

Hopper Capacity

|

6.1 cubic feet

|

6.1 cubic feet

|

9.0 cubic feet

|

|

Standard Tire Configuration

|

(9) 8 inch dia. x 2 inch solid rubber

|

(9) 8 inch dia. x 2 inch solid rubber

|

(4) 4.10 x 3.50 pneumatic front +

(3) 8 inch dia. x 2.5 inch solid rubber rear

|

|

Engines

|

13 HP Honda

14 HP Kohler

|

20.3 HP Honda

|

20.3 HP Honda

|

|

Engine Starting System

|

Recoil

|

Electric

|

Electric

|

Electric

|

|

Fuel Capacity

|

1.6 gal.

|

2.3 gal.

|

3.3 gal.

|

|

Standard Auger Configuration

|

(2) cast 6 inch dia. x 9 inch lg.

|

(2) cast 6 inch dia. x 9 inch lg.

|

(3) cast 6 inch dia. x 9 inch lg.

|

|

Optional Auger Configurations

|

(2) cast 5 inch dia. x 9 inch lg.

(1) welded 8 inch dia. x 18 inch lg.

|

(2) cast 5 inch dia. x 9 inch lg.

(1) welded 8 inch dia. x 18 inch lg.

(1) welded 10 inch dia. x 18 inch lg.

|

(3) cast 5 inch dia. x 9 inch lg.

(3) welded 8 inch dia. x 18 inch lg.

(3) welded 10 inch dia. x 18 inch lg.

|

|

Hollow Auger Shaft (to extrude rebar)

|

Optional

|

Optional

|

Not available

|

|

Drive System

|

Automatic centrifugal clutch to enclosed 8:1 gear reducer; final auger drive chain & sprocket

Extrusion process provides self-propulsion

|

|

Steering

|

Tie rod with 40 inch steering handle

|

|

Brake

|

Friction pad on steering handle

|

|

OTHER AVAILABLE MODELS:

MC655 Same as MC650, but with modified frame allowing extrusion under existing guardrail.

MC750 Same as MC650, but with two continuously turning auger assemblies, one mounted on the left and one on the right, allowing immediate changeover from right to left hand

extrusion.

|

05 - Curbilder product category

13 - horsepower of motor

HR - motor type, H for Honda, K for Kohler, second digit R for recoil, E for electric start

650 - series of Curbilder

06 - auger diameter

S - type of auger, S for solid, H for hollow

S - type of wheels, S for solid rubber, P for pneumatic

|

Models and Accessories

|

|

Standard Models

|

|

05-13HR-550-06SS

|

STANDARD MODEL - MC550 6 inch solid auger Commercial Curbers - 13 HP Honda

recoil

|

|

05-13HE-650-06SS

|

STANDARD MODEL - MC650 6 inch solid auger Commercial

Curbers - 13 HP Honda Elec Start

|

|

05-13HE-655-06SS

|

STANDARD MODEL - MC655 6 inch solid auger

Commercial Curbers - 13 HP Honda Elec Start

|

|

05-13HE-750-06SS

|

STANDARD MODEL - MC750 twin 6 inch solid augers

Commercial Curbers - 13 HP Honda Elec Start

|

|

05-20HE-850-08SPS

|

STANDARD MODEL - MC850 8 inch solid auger Commercial

Curbers - 20HP Honda Elec Start

|

|

05-20HE-900-06SPS

|

STANDARD MODEL - MC900 6 inch solid auger Commercial

Curbers - 20HP Honda Elec Start

|

|

MC550 Series

|

|

05-13HR-550-05SS

|

MC550 5 inch solid auger Commercial Curbers - 13 HP Honda recoil

|

|

05-13HR-550-05HS

|

MC550 5 inch hollow auger Commercial Curbers - 13 HP Honda recoil

|

|

05-13HR-550-06HS

|

MC550 6 inch hollow auger Commercial Curbers - 13 HP Honda recoil

|

|

05-13HE-650-05SS

|

MC650 5 inch solid auger Commercial Curbers - 13 HP Honda Elec Start

|

|

05-13HE-650-05HS

|

MC650 5 inch hollow auger Commercial Curbers - 13 HP Honda Elec Start

|

|

MC650 Series

|

|

05-13HE-650-06HS

|

MC650 6 inch hollow auger Commercial Curbers - 13 HP Honda Elec Start

|

|

05-13HE-650-08SS

|

MC650 8 inch solid auger Commercial Curbers - 13 HP Honda Elec Start

|

|

05-13HE-650-08HS

|

MC650 8 inch hollow auger Commercial Curbers - 13 HP Honda Elec Start

|

|

05-13HE-655-05SS

|

MC655 5 inch solid auger Commercial Curbers - 13 HP Honda Elec Start

|

|

MC750 Series

|

|

05-13HE-750-05SS

|

MC750 twin 5 inch solid augers Commercial Curbers - 13 HP Honda Elec Start

|

|

05-13HE-750-05SS

|

MC750 twin 5 inch hollow augers Commercial Curbers - 13 HP Honda Elec Start

|

|

05-13HE-750-06HS

|

MC750 twin 6 inch hollow augers Commercial Curbers - 13 HP Honda Elec Start

|

|

MC850 Series

|

|

05-20HE-850-06SPS

|

MC850 6 inch solid auger Commercial Curbers - 20HP Honda Elec Start

|

|

05-20HE-850-06HPS

|

MC850 6 inch hollow auger Commercial Curbers - 20HP Honda Elec Start

|

|

05-20HE-850-08HPS

|

MC850 8 inch hollow auger Commercial Curbers - 20HP Honda Elec Start

|

|

05-20HE-850-10SPS

|

MC850 10 inch solid auger Commercial Curbers - 20HP Honda Elec Start

|

|

MC900 Series

|

|

05-20HE-900-06HPS

|

MC900 6 inch hollow auger Commercial Curbers - 20HP Honda Elec Start

|

|

05-20HE-900-08SPS

|

MC900 8 inch solid auger Commercial Curbers - 20HP Honda Elec Start

|

|

05-20HE-900-10SPS

|

mc900 10 inch solid auger Commercial Curbers - 20HP Honda Elec Start

|

|

Optional Equipment for MC550, MC650, MC655 and MC750

|

|

20HP

|

20 HP Honda twin cylinder engine in lieu of 13 HP Honda (MC650 only)

|

|

14HP

|

14 HP Kohler engine in lieu of 13 HP Honda

|

|

PN-TIRES

|

4.10/3.50 pneumatic tires (6) in lieu of 8 x 2 inch solid rubber

|

|

RHOP

|

Removable hopper side plate

|

|

SPL

|

Single point lifting lug

|

|

AWH

|

Additional Wheelbarrow Hopper, right or left hand (not available for MC655)

|

|

Optional Equipment for MC850 and MC900

|

|

SPLL

|

Single point lifting lug - Optional Equipment for MC850 and MC900

|

|

RH

|

Reversible hopper - Optional Equipment for MC850 and MC900

|

|

RHSP

|

Removable hopper side plate - Optional Equipment for MC850 and MC900

|

|

Commercial Curb Forms

|

|

CCF5

|

Commercial Curb Forms for 5 inch Miller Augers

|

|

CCF6

|

Commercial Curb Forms for 6 inch Miller Augers

|

|

CCF8

|

Commercial Curb Forms for 8 inch Miller Augers

|

|

CCF10

|

Commercial Curb Forms for 10 inch Miller Augers

|

|

Tools and Accessories

|

|

PA-84-30

|

84 aluminum handle 30 inch plain edge

|

|

PA-84-30S

|

84 aluminum handle 30 inch plain edge (L-16 Brace)

|

|

PA-84-36

|

84 aluminum handle 36 inch plain edge

|

|

PA-84-36S

|

84 aluminum handle 36 inch plain edge (L-16 Brace)

|

|

SA-84-30

|

84 aluminum handle 30 inch one edge serrated

|

|

SA-84-30S

|

84 aluminum handle 30 inch one edge serrated (L-16 Brace)

|

|

SA-84-36

|

84 aluminum handle 36 inch one edge serrated

|

|

SA-84-36S

|

84 aluminum handle 36 inch one edge serrated (L-16 Brace)

|

|

LA-66-36

|

66 anodized aluminum handle 36 inch blade

|

|

LA-84-36

|

84 anodized aluminum handle 36 inch blade

|

|

HR-180A

|

Hand Roller, 15 x 18 inch, 150 lb

|

|

HTS 8X8

|

8x8 inch Hand Tamp with steel handle

|

|

L-10-P

|

30 plain edge blade

|

|

L-10-S

|

30 serrated 1 edge blade

|

|

L-11-P

|

36 plain edge blade

|

|

L-11-S

|

36 serrated 1 edge blade

|

|

L-16

|

Stamped steel brace

|

|

L-7B

|

84 aluminum handle

|

|

L-9

|

Aluminum handle support tube

|

|

LR-1

|

36 landscape rake head

|

|

91000-14

|

Hand roller bearing

|

Commercial Curbers: 7 Different Commercial Curb Machine Models

For over fifty years the Miller MC Series Curbers have offered unequaled performance and versatility for the placement of freestanding curb. Curb and Gutter machine

These simple and efficient self-propelled machines operate on the extrusion principle and provide the most economical means available of constructing small to mid-sized continuous curb from either

concrete or asphalt.

This quick and efficient process drastically reduces the high labor costs associated with hand formed and poured curb and produces high quality, extremely dense curb at a rate of up to 15 fpm (up

to 30 fpm for MC900). Millerâs exclusive interchangeable extrusion auger assemblies give each Curber the capacity to extrude more shapes and sizes than any machine in its class, from 3-1/2â³ to 18â³

high curb.

A wide variety of options allow these machines to meet the toughest specification work

Miller Advantages

- Every model will extrude concrete or asphalt

- Four interchangeable extrusion assemblies with auger diameters from 5â³ to 10â³

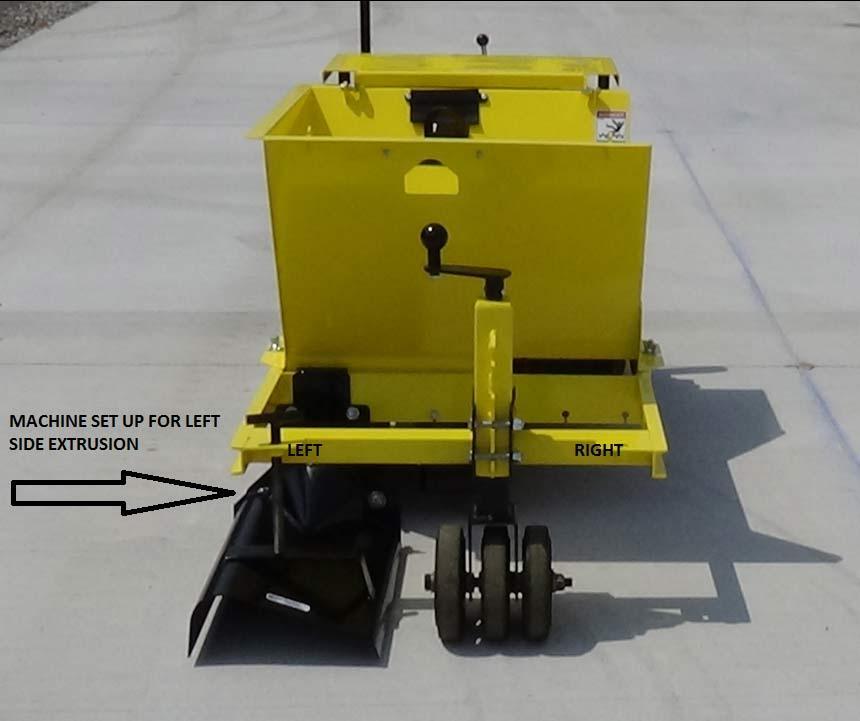

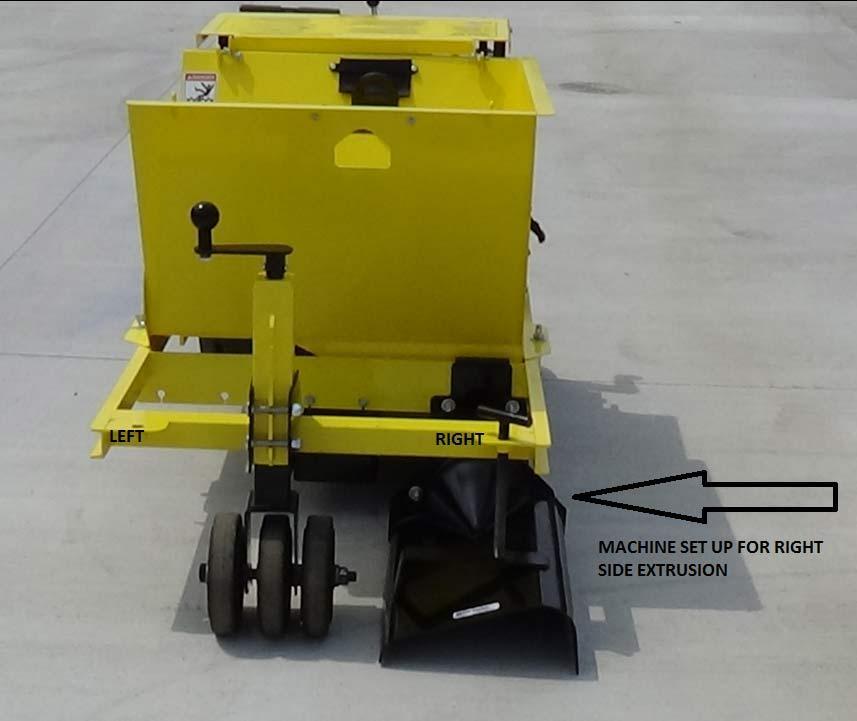

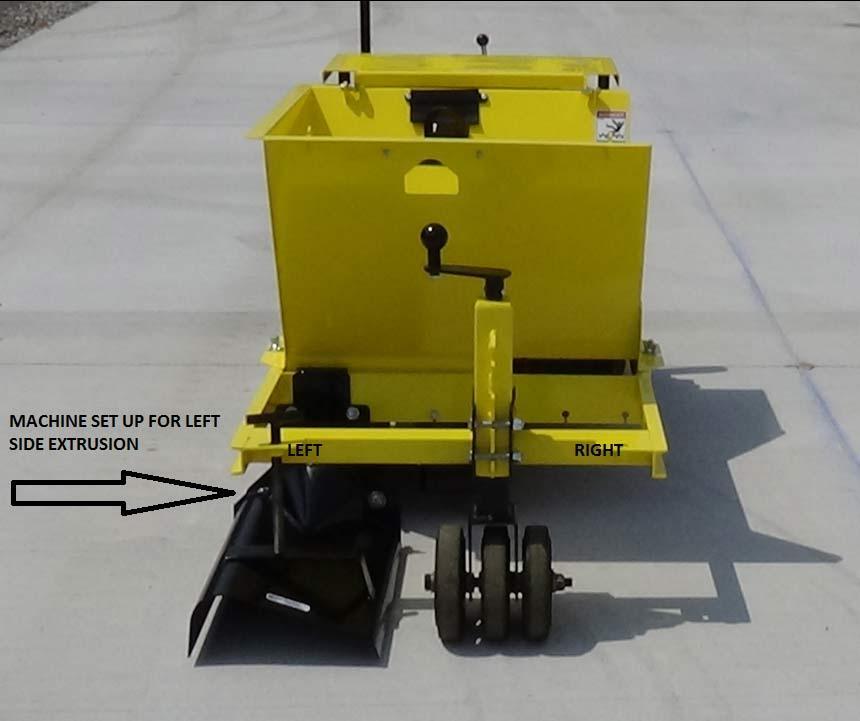

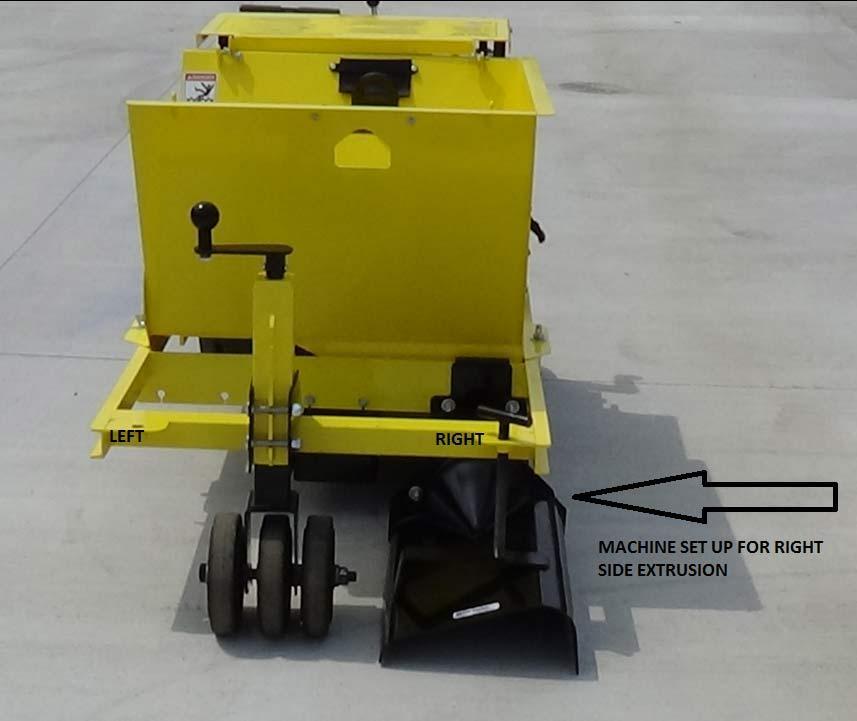

- Extrude from right or left side of the machine

- Place curb within 1â³ of an obstacle

- Extrude steel rod through the curb center (optional hollow auger assembly)

- Extrude over pins (optional form)

- Two-piece 5â³, 6â³ and 8â³ cast auger allowing four separate wear surfaces for extended life

- Easy access and removal of all extrusion components for maintenance and quick clean-up

- Nearly 2,000 curb choices with custom shapes available at no additional cost.

|

MC 550/650

The MC 550/650 Curb Machines are the bread and butter of all the models we make. They are very versatile curb machines that are designed to handle everything from extruding curb in a

parking lot, trench curb, barn curb or curbing along a city street, county road or highway. The only difference between the 2 models is the 550 has a 13 HP Honda recoil start engine and the

650 has a 13 HP Honda electric start engine.

|

|

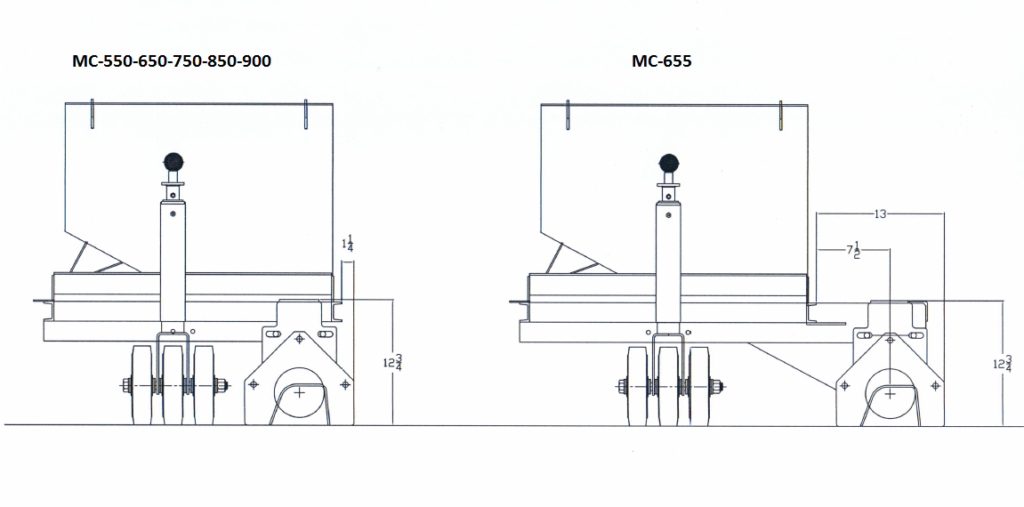

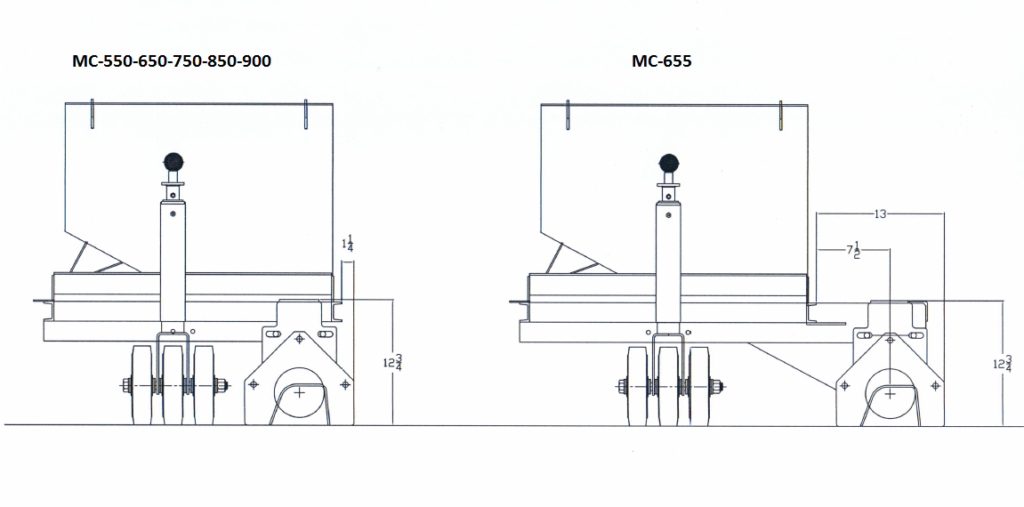

MC 655

This machine has an auger housing that is offset by 12â³ to allow the MC 655 Curb Machine to extrude curb under an existing guardrail.

|

|

MC 750

The MC 750 Curb Machine has an auger housing on both the right and left side and is designed for the customer who wants to be able to switch from a left hand extrusion to right hand

extrusion quickly while at the job-site. Keep in mind for this curb machine you will need 2 curb forms (one for the right and one for the left) if the curb is asymmetrical.

|

|

MC 850

This machine is designed for the customer who has large concrete curbs ( typically taller than 13â³) they need to extrude. The MC 850 Curb Machine has a tubular frame, a 20 HP 2 Cylinder

Honda Engine, a heavy duty clutch, 2.5â³ diameter wheels, heavy duty forks, heavy duty auger housing and a heavy duty motor mount.

|

|

MC 900

The MC 900 Curb Machine is designed for the customer who has miles and miles of roadway curbing projects or has very large (typically 13â³ or taller) concrete curbs they want to extrude With

3 sections of augers (all other models only have 2) in it, the 900 is the longest and fastest machine we make, making it ideal for miles and miles of roadway curbing projects.

|

|

Curb and Gutter Machine

This machine is designed to extrude either a 18â³ or 24â³ curb and gutter. This machine is built with 2 auger housings next to each other. If you would like to do a 24â³ curb and gutter

(CFD-1887), the machine is equipped with a 2-8â³ auger housings. If you would like to do a 18â³ curb and gutter (CFD-1886) the machine is equipped with 1-8â auger housing and 1-6â³ auger

housing. This machine is the same length as our MC 900, but is 56.25â³ in width. This machine requires a graded, compacted base that is at least 56.25â³ in width. Either machine comes with

vibration and 2 outrigger arms to provide stability. Please note, this machine does not have any capabilities to change the grade. Any imperfection in the grade will result in the curb

having the same imperfections.

|

Curb Mix Information

BECAUSE AVAILABLE MIX AND JOB CONDITIONS WILL VARY FROM ONE AREA TO ANOTHER, THE FOLLOWING CONCRETE AND ASPHALT MIX SPECIFICATIONS CAN BE USED AS GUIDES FROM WHICH TO DETERMINE EXACT MIX

REQUIREMENTS:

Aggregate/Sand Information:

The size of stone and the amount of stone in the mix is very important. It is the stone that the auger pushes. A mix that has stone of a large enough size and quantity, will move through the Curber

easier and quicker than a mix that does not. A mix with the proper size and quantity of stone puts less stress on the drive system and the wear components. Recommended minimum size of stone is 3/8

inch. The larger the curb size, the larger the stone should be and the more stone there should be. Maximum stone size is 3/4 inch.

The larger the stone and the more stone there is in the mix, the more finish work may be required. But, the larger the stone and the more stone there is in the mix, the easier and faster the mix

will move through the Curber. The easier the mix moves through the Curber, the longer the wear life of the wear components. As the content of stone is increased the content of sand should be

equally decreased. Typically a blend of Sand 60 percent and Stone 40 percent is a good starting point. A mix that has stone of too small a size and quantity, and or a high sand content, WILL PACK

rather than move through the Curber. With this kind of mix the auger will spin many more times to move the mix. This extra spinning will cause excessive wear to all of the wear components. This

kind of mix can wear out an auger, compaction tube, or curb form within 1500 to 2000 lineal feet of curb. This kind of mix will also cause the Curber to move very slow or not at all.

|

|

|

Minimum stone size 3/8 inch

|

Maximum stone size 3/4 inch

|

Recommended Mix Specifications:

CONCRETE CURB

For one cubic yard of concrete:

- 0 inch to 1 inch slump

- Cement: 660# (7 sacks)

- Sand: 1,600 #, 5 percent moisture

- Aggregate: 1,400 #, 3/8 inch

- Water: Approximately 15 gallons

Keep loads to 3 yards when possible. Water content varies according to materials and moisture content. Larger loads and higher air temperatures may require more water to maintain slump. Add water

at job site only. Work materials to dry side. Retardant should be used at the manufacturers recommended minimum amount. This amount may be adjusted based on local conditions. Air entrainment should

be added at approximately 5 percent. This amount may be adjusted based on local conditions.

|

ASPHALT CURB

|

|

|

PRODUCT

|

WEIGHT PER TON

|

PERCENTAGE

|

|

3/8 inch Stone

|

590

|

29.50 percent

|

|

Washed Sand

|

1250

|

62.50 percent

|

|

Liquid Asphalt

|

160

|

8 percent

|

|

Aggregate should be thoroughly washed and dried. Virgin mix is recommended. Liquid asphalt content by weight for virgin mix should be 8 percent. If using recycled mix and the curb does not stand

the liquid asphalt content will need to be raised. Recycled mix usually has too many foreign substances in it and it usually does not have enough liquid asphalt in it. The liquid asphalt content

may also have to be raised if the mix has slag, unwashed aggregate, or other absorptive materials in it. Working temperature â 200 to 270 degrees Fahrenheit.

USE THE FOLLOWING CALCULATIONS TO HELP DETERMINE THE QUANTITY OF MIX REQUIRED FOR ANY GIVEN CURB FORM:

ASPHALT:

- 1,920 ÷ cross sectional area of the curb form = lineal feet per ton

- Cross sectional area of the curb (in square inches)

CONCRETE:

- 3,888 ÷ cross sectional area of the curb form = lineal feet per ton

- Cross sectional area of the curb (in square inches)

NOTE:

- See Choosing the Appropriate Auger Size info sheet to determine the square inch area of the curb form.

- Refer to Curb Form Design Sheets for Curb Shapes and Data.

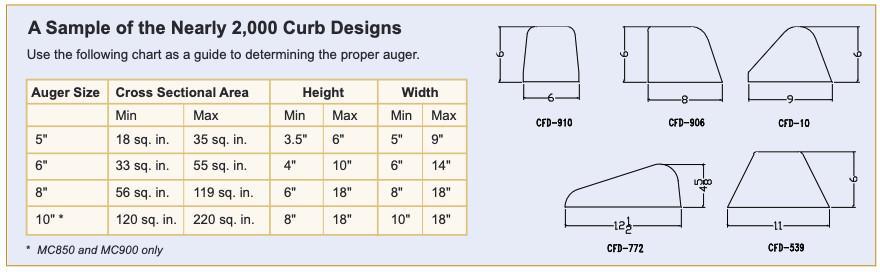

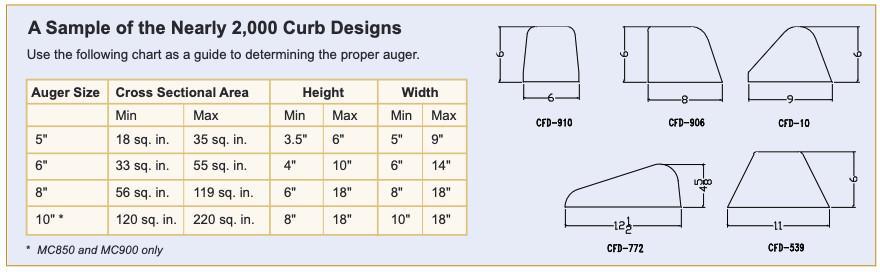

Choosing the Appropriate Auger Size

Miller Curbers can be equipped with one of four (4) different extrusion auger diameters.

These diameters are 5 inch, 6 inch, 8 inch and 10 inch.

Auger assemblies are interchangeable between all Miller Curber models with the exception of the 10 inch diameter assembly which is only available on the higher horsepower models Mc850 and MC900.

Each of these auger assemblies works best with a particular range of curb sizes, measured in cross sectional area. The relationship between the cross sectional area of the curb and auger size is

critical and must be given careful consideration when matching a particular curb with the correct auger assembly.

IMPROPER SIZING CAN CAUSE EXCESSIVE COMPONENT WEAR, REDUCED LIFE, POOR PERFORMANCE OR COMPLETE FAILURE TO OPERATE.

The following table is a general guide to choose the correct auger assembly for your application. Always consult the factory for curb form and auger size recommendations. Some curb shapes may

require deviation from this chart.

Because most extruded curb is between 33 and 55 square inches in cross sectional area 90 percent of all machines are equipped with the standard 6 inch diameter auger.

|

5 inch

|

18

|

32

|

3 1/2 inch

|

6 inch

|

5 inch

|

9 inch

|

|

6 inch

|

33

|

55

|

4 inch

|

10 inch

|

6 inch

|

14 inch

|

|

8 inch

|

56

|

119

|

6 inch

|

18 inch

|

8 inch

|

18 inch

|

|

10 inch

|

120

|

220

|

8 inch

|

18 inch

|

10 inch

|

18 inch

|

The most common mistake when sizing forms and augers is choosing a curb form which is too small for a particular auger size.

For example, a curb shape that is a simple rectangle 6 inch wide x 4 inch high would have a cross sectional area of 24 square inches. This puts it clearly in the 5 inch diameter auger range.

Attempting to do this shape with a 6 inch auger would result in a number of problems. The amount of material discharged by the 6 inch auger into the form would be so great in relation to the cross

sectional area of the curb that the machine would not be able to discharge, or extrude, the material fast enough. In effect, the mold becomes a severe bottleneck. As a result, excessive pressure

would be created in the form. When the density of the material in the form reached the point where it could be compacted no further the excessive pressure in the form would cause the machine to

actually lift, allowing material to squeeze out from under all sides of the form. This would reduce the pressure in the form but not produce an acceptable curb. Excessive pressure may also be

transmitted back through the drive train causing repeated disengagement of the safety torque arm and/or shear bolt breakage. To remedy this problem, auger diameter must be reduced or curb area

increased.

The second most common mistake when sizing forms and augers is choosing a form that is too large for a particular auger size. Under sizing the auger will not cause problems as severe as over sizing

but will affect machine performance. Curb density and finish may be adversely affected and extrusion speed will be reduced. It is possible to add 5-10 percent to the recommended upper limit for any

given auger size and still extrude satisfactorily. In the most severe case of an undersized auger the machine may discharge enough material into the form to propel itself, but inadequate density

may result in a loose curb with open finish and surface voids that may not stand. Always consult the factory for recommendations on proper auger size and curb form choices.

Auger assemblies can be provided as either hollow, allowing 3/8 inch diameter reinforcing rod to be fed through the hollow auger shaft and placed in the finished curb, or as solid. The primary

difference in these systems is that the in the hollow the augers are installed on a tubular shaft that is 1-1/4 inch OD by 3/4 inch ID allowing the reinforcing rod to pass through. The solid system

uses a 1-1/4 inch diameter solid shaft.

The auger assembly can be placed on either the right or left side of the machine. The machineâs right and left are determined by standing at the end of the machine where the curb form is attached

and looking at the open end of the form. From this perspective, if the form and auger assembly are on the left then this would be considered left hand extrusion. Unless otherwise specified at the

time of ordering all machines

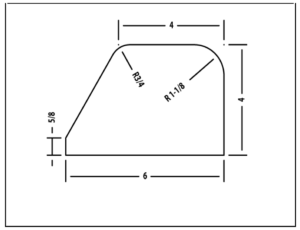

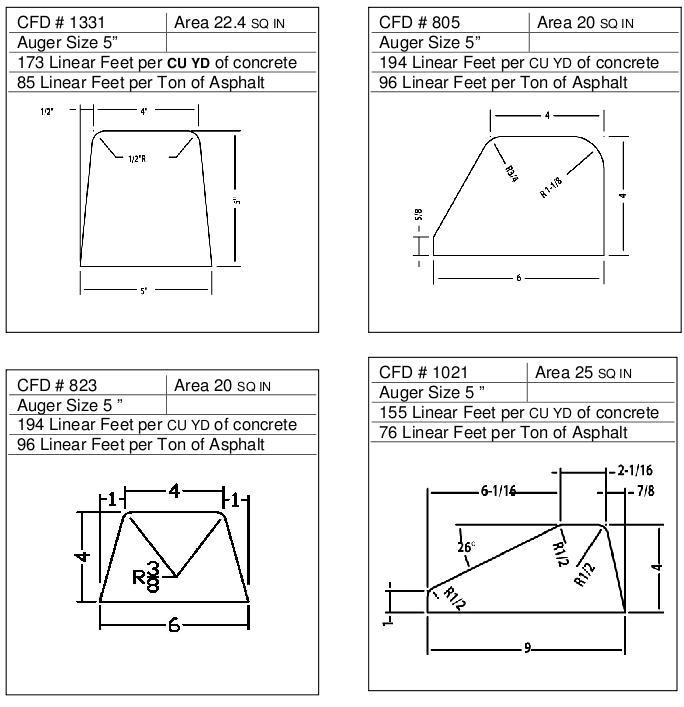

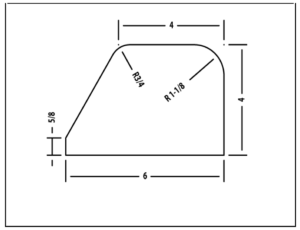

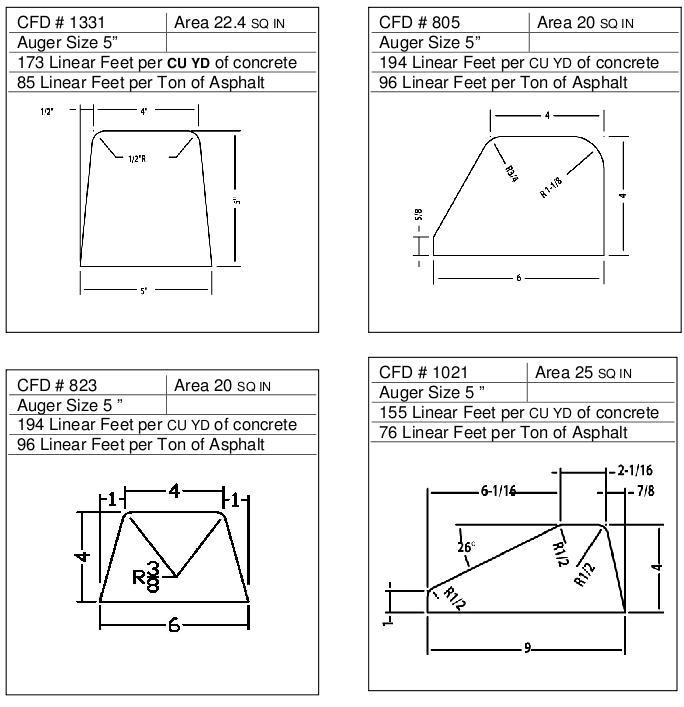

Sample Curb Forms for Miller Curbers Equipped with 5 inch Auger Assembly

Sample Curb Forms for Miller Curbers Equipped with 6 inch Auger Assembly

Sample Curb Forms for Miller Curbers Equipped with 8 inch Auger Assembly

These different options for your Miller Curber Commercial Curbilder are available.

Your Choice of Hopper:

Included in the purchase of your machine you get to select one of the 2 hopper configurations. The machines are built so they can extrude a curb on either the LEFT or RIGHT side of the machine.

|

|

|

Left Side Extrusion

|

Right Side Extrusion

|

If you would like to extrude on either side, then you would need the reversible hopper.

If you only plan to Extrude on the LEFT hand side (Right and Left is determined by watching the machine work away from you). You could select the wheelbarrow hopper. This hopper can hold more

material and has a larger cut out so you can easily dump a load of material into the hopper with a wheelbarrow.

With either hopper choice you could have an optional removable hopper side plate. This plate pins into one side of the hopper and when it is in all 4 sides of the hopper are the same size. Some

customers like this when they load from a cement truck because it reduces the amount of mix that can get spilled from the hopper.

|

|

|

Wheelbarrow Hopper

|

Removable Side Plate

|

|

(Rebar inserted into Hollow Auger Shaft)

|

|

Lifting Lug This is a single point that you can lift the machine from

|

Hollow Auger This will allow you to pass rebar from the machine into your curb. If you would like a hollow augers instead of the standard solid auger

|

|

Cast Compaction Tube

This compaction tube is made from the same material as the augers. So it’s a white iron compaction tube. This compaction tube will last 15 times as long as a steel compaction tube that

comes with the machine. If you would like the cast compaction tube

|

|

Rear Swivel Wheel

This option is designed so that if you are curbing back to a solid object, like a building, that you can get the machine as close to the building as you can before you get the machine off the

curb. In the past guys would lift the machine off the curb. This option allows you to raise the machine up, rotate the wheels and push the machine off the curb

|

|

Vibration Kit

This can be added to any machine to assist in getting concrete into the augers to keep the augers full, please consult us to make sure this option will work in your application and machine.

|

|

Hydraulic Breaking System

The hydraulic braking system is activated with a motorcycle type hand lever. It also features a locking mechanism that serves as a parking brake. When the lever is activated, hydraulic fluid

flows to two calipers each located on the front forks. Brake pads in the calipers apply friction to each 3/16” thick x 7” diameter disks which are directly attached to the axles

thus braking all four front wheels. The primary use of the brake is to prevent the curb extruder from rolling when extruding down hill. Currently available with machines with solid wheels

|

|

Pneumatic Tires: if you would like pneumatic tires in lieu of solid tires

|

Limited Warranty for Equipment

The Miller Curber Company guarantees to the original purchaser the frame and metal components of the equipment manufactured by Miller Curber Company to be free from

defects in material and workmanship for six (6) years from date of original shipment from Miller Curber Company. This warranty excludes all equipment, parts, components and accessories not

manufactured by Miller, including, but not limited to: engines, transmissions, pumps, cylinders, batteries, tires, bearings, belts, etc. Such products are warranted by their respective

manufacturer, whose warranty will be the governing warranty for that particular product. Individual manufacturersââ¬â¢ warranties are available upon request.

This is a LIMITED WARRANTY. This warranty is expressly in lieu of all other warranties, express or implied, including the warranties of merchantability and fitness for

use and all other obligations or liabilities on our part. And we neither assume nor authorize any other to assume for us, any other liability in connection with the sale of any Miller Curber

Company products. There are no warranties which extend beyond the description on the face hereof. To validate this warranty for equipment the registration form which accompanies each machine must

be completed and returned to the factory by the customer within two (4) weeks after the purchase of the machine.

Emission Control System Warranty for Emissions Equipment Installed on Miller Curber Models MC-850/900

The Miller Curber Company guarantees to the original purchaser of all of the emissions equipment installed on Miller Curber Model MC850/900 to be free from defects in

material and workmanship for two (2) years from the date of original shipment from Miller Curber Co. Emission equipment includes: 1) welded steel fuel tank, 2) sealing, tethered fuel cap, c) low

permeation fuel supply hose, and d) low permeation fuel vapor hose. Exclusions: Failures other than those resulting from defects in material and workmanship are not covered by this warranty. This

warranty does not extend to emission control systems or parts which are affected or damaged by owner abuse, neglect, improper maintenance, misuse, misfueling, improper storage, accident and/or

collision, the incorporation of, or any use of, any add-on or modified parts, unsuitable attachments, or the unauthorized alteration of any part.

Limited Warranty for Hand Tools

The Miller Curber Company guarantees to the original purchaser the hand tools manufactured by Miller Curber Company to be free from defects in material and workmanship

for ninety days from the date of purchase. The obligation of the Miller Curber Company under this warranty shall be limited to the repair or replacement of any product or parts thereof which may

prove to be defective in material or workmanship, to the satisfaction of Miller upon inspection, under normal use and service. This warranty shall not apply to any product or part of said product,

which in the judgment of the Miller Curber Company, was not operated, or maintained correctly, in every respect, as outlined in the manual or information which accompanies each product. This

warranty does not apply to failure occurring as a result of abuse, misuse, negligent repairs, corrosion, erosion, normal wear and tear, alterations or modifications made to the product without the

express written consent of the Miller Curber Company.

The total liability of Miller Curber Company with respect to their sale of products or services furnished hereunder, in connection with the performance or breach

thereof, or from the sale, delivery, installation, repair or technical direction covered by or furnished under the sale, whether based on contract, warranty, negligence, indemnity, strict

liability, or otherwise shall not exceed the purchase price of the unit of product upon which such liability is based.

Since Miller Curber Company has no means of controlling the final use of its products by the consumer or user, it is the responsibility of the immediate seller(s) to

inform the user of each product of the purposes and conditions for which the product may be fit and suitable, including the precautionary measures which must be taken in order to insure the safety

of the user and of third persons and property.

Both the seller and the manufacturer shall be held free and harmless from any liability from injury to any person(s), loss or damage to any property, direct,

incidental, consequential, or otherwise, resulting from the accidental, negligent, altered, abused or misused operation of the machine. Before using, the user shall determine the suitability of the

product for the intended use, and the user assumes all risk and liability what-so-ever in connection with such use. Any product built to customer design shall be warranted as above only with

respect to materials and workmanship. The Miller Curber Company shall be held harmless from any injury or damage resulting from such custom design, or functional dissatisfaction of such product.

Miller Curber Company reserves the right to modify, alter and improve any part or parts without incurring any obligation to replace any part or parts previously sold without such modified, altered

or improved part or parts. Authorization from the Miller Curber Company is required prior to any warranty work being performed. Any warranty work authorized by the Miller Curber Company will be

performed only at the location(s) authorized and by the person(s) authorized. When warranty repairs require specific procedures, repairs will be performed as instructed by the Miller Curber

Company. Authorization from the Miller Curber Company is required prior to any products or parts of products being returned to the factory for warranty consideration.

All returns must be shipped prepaid and are subject to inspection.

This warranty does not obligate the Miller Curber Company to bear the cost of service, labor, mileage, delivery charges, or other expenses that have not been

previously authorized by the Miller Curber Company. In the event that new parts are shipped to a dealer/user to replace alleged defective parts, prior to Miller Curber Company receiving the alleged

defective parts, and prior to Miller Curber Company determining that parts are defective and covered under warranty, the new parts will be shipped and invoiced as a normal parts order. The

dealer/user invoiced under these conditions is liable for payment of the parts invoice. At such time that the returned parts are determined to be defective, and covered under warranty, a credit to

account will be issued for the warranted amount.

|

ALL STEEL HAND ROLLER

- 14 inch O.D. x 15 inch long drum with beveled edges

- Drum is ball bearing mounted on a 1 inch cold-rolled steel shaft

- 1 inch diameter steel handle counter-weighted to automatically return to an upright position

- Handle mounted on one side only to allow rolling close to a building or obstacle

|

|

ALL STEEL HAND TAMP

- Steel tamp head is more durable than cast iron tamp head

|

|

ALL ALUMINUM LANDSCAPE RAKE

- Blades are aluminum and available in 36 inch

- Handles are 66 and 82 inch long and 1-5/32 inch diameter anodized (non-oxidizing) aluminum and are reinforced at all stress points with hardwood dowels

- Two L-9 aluminum tubular blade supports are standard

|