CPX Refrigerated Air Dryers

The CPX Refrigerated Air Dryers For All Applications

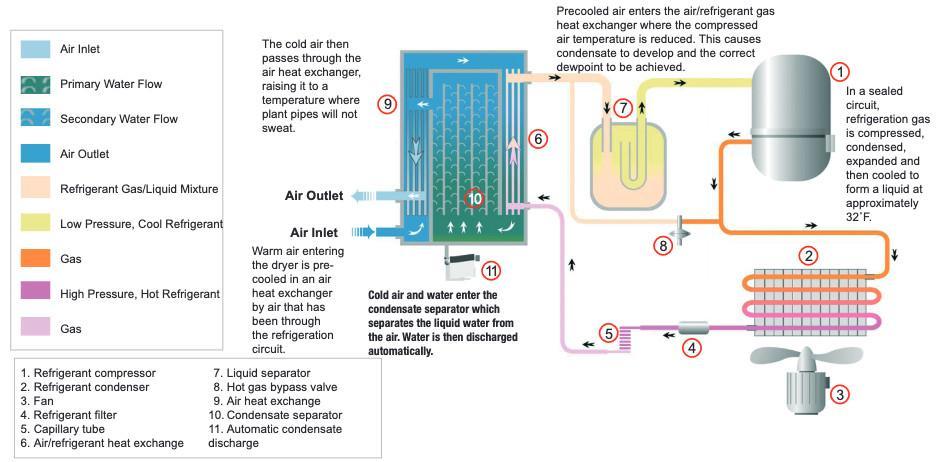

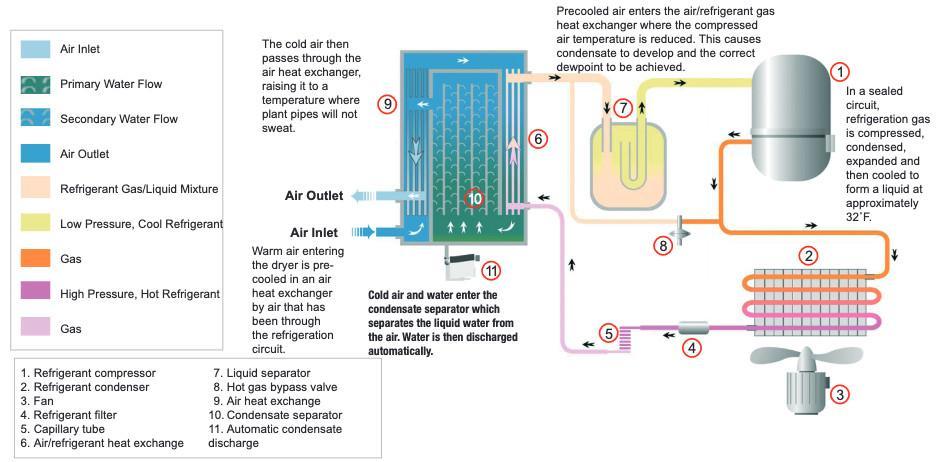

Sized to handle 12 to 2966 cfm, the CPX dryers fit any application. Extremely quiet and reliable, CPX dryers deliver dry air with minimal pressure drop. These dryers are machines designed for

treating compressed air. By using the refrigerant characteristics of certain fluid, these dryers lower the temperature of the compressed air, causing water vapor to condense and discharge prior to

it entering any distribution system.

Compressed Air Water Contamination

Atmospheric air contains water in vapor form in different volumes according to the ambient conditions. Under compression, this water is drawn in along with the air. After compression, the air and

water are then discharged to the distribution system, with some of the water content normally being removed by a compressed air aftercooler and then discharged.

However, a large proportion of the water vapor content remains in the compressed air, moving in the pipe distribution system as the air is consumed.

|

Compressed air may undergo further cooling in the piping, as a result of ambient temperature and/or due to expansion, resulting in liquid water lying in the pipe distribution system,

receivers and pneumatic equipment.

|

|

As time passes, the condensate can cause serious damage to pipes and applications, resulting in production downtime and higher maintenance costs. During processes, where compressed air comes

into contact with the final product, it can even damage the product itself.

|

Water Contamination Risks

Corrosion in the network:

- Increasing pressure drop due to deterioration of the air network with increasing pipe scale and rust. Damage to joints will cause air leaks, significantly increasing the cost of plant

production.

Malfunction of the pneumatic equipment:

- Excess water will lead to malfunctioning of equipment and instrumentation, a reduction of component life and an increase in production losses and manufacturing costs.

Product contamination:

- The efficiency of the production process can reduce product spoilage caused by product contamination; fitting moisture separators improves air quality. During painting, condensate causes

imperfections on the finished product creating future corrosion areas. In pharmaceutical and electronic applications, condensate product contamination can be harmful and/or extremely expensive.

|

CPX Preformance Specificatons

|

|

Model

|

cfm at

100 psig

|

Max.

Pres

|

Electrics

V/Ph/Hz

|

Weight

(lbs)

|

LxWxH (in)

|

Refrig

|

Noise

(dBA)

|

|

CPX-10

|

12

|

232

|

15/230/60/1

|

42

|

14 20 18

|

R-134a

|

50

|

|

CPX-20

|

21

|

232

|

15/230/60/1

|

42

|

14 20 18

|

R-134a

|

50

|

|

CPX-30

|

30

|

232

|

15/230/60/1

|

44

|

14 20 18

|

R-134a

|

47

|

|

CPX-40

|

43

|

232

|

15/230/60/1

|

55

|

14 20 18

|

R-134a

|

53

|

|

CPX-60

|

65

|

232

|

15/230/60/1

|

60

|

14 20 18

|

R-134a

|

53

|

|

CPX-80

|

83

|

232

|

15/230/60/1

|

97

|

15 20 30

|

R-404A

|

57

|

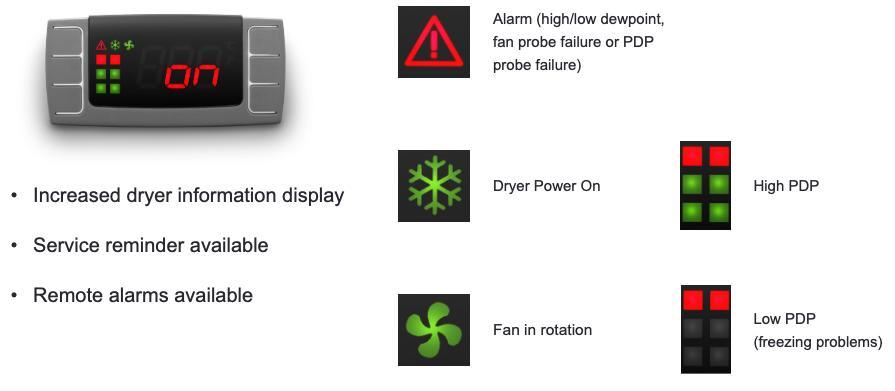

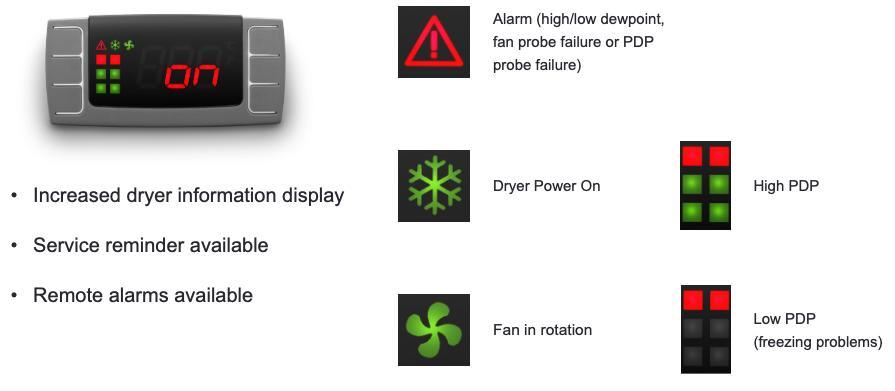

PDP (Pressure Dew Point) lndicator

CPXHT - High Temp Dryers

The CPXHT dryers are a perfect complement to the RCP line of reciprocating air compressors. With a maximum inlet temperature of 180 ËšF, no aftercooler is required.

The CPXHT dryers are easy to install and have a compact design. Supplied with 115 Volt power means no special wiring is required and the space saving design incorporates refrigerated air dryer,

moisture separator, and electronic water drain.

|

Standard Features:

- Equipped with stainless steel/copper heat exchanger

- Eliminates water, oil and dirt from air systems

- Prevents damage to tools and cylinders, adding to their longevity

- Fewer finished product defects

- Prevents “fisheye” paint splotches

- Reduces operational downtime

- Increases profitability and productivity

- Eliminates air line purging

- Compact design for small footprint

- Quality components for efficient cooling

- Internal layout and enclosure allow for quiet operation

|

|

|

No Air Loss Condensate Drain

|

|

All models are equipped with a smart condensate discharger. Carefully sized for each model,

it assures exceptional reliability and efficiency in discharging water, without compressed air.

In case of malfunction, an alarm signal is displayed.

- It discharges only water, NOT compressed air.

- Silent, eliminating noise pollution.

- Comes with standard 1 year warranty.

|

|

CPX Preformance Specificatons

|

|

Model

|

50ËšF PDP

cfm at 100 psig

|

Use

with

|

Electrics

V/Ph/Hz

|

Oper.

kW

|

Heat

Exchanger

|

Max

psig

|

Refrig.

|

Weight

(lbs)

|

LxWxH (in)

|

Conn.

(NPT)

|

|

CPXHT-25

|

25

|

5 and 7.5 hp

|

115/1/60

|

1/4

|

SS/Copper

|

232

|

R-134a

|

57

|

14 15 18

|

3/4

|

|

CPXHT-50

|

50

|

10-15 hp

|

115/1/60

|

1/4

|

SS/Copper

|

232

|

R-404A

|

108

|

18 23 31

|

1

|

|

CPXHT-75

|

75

|

20 hp

|

115/1/60

|

1/2

|

SS/Copper

|

232

|

R-404A

|

168

|

18 23 31

|

3/4

|

|

CPXHT-100

|

100

|

25 hp

|

115/1/60

|

3/4

|

SS/Copper

|

232

|

R-404A

|

231

|

18 23 41

|

3/4

|

|

CPXHT-125

|

125

|

30 hp

|

115/1/60

|

3/4

|

SS/Copper

|

232

|

R-404A

|

236

|

18 23 41

|

3/4

|