|

Models

|

|

Core Specs

|

|

Model

|

Length

|

Arbor

|

Weight

|

|

S14B

|

14 inch (35.5 cm)

|

1.5 inch

|

36 lbs (16.4 kg)

|

|

S24B

|

24 inch (61.0 cm)

|

1.5 inch

|

56 lbs (25.5 kg)

|

|

S24C

|

24 inch (61.0 cm)

|

2 inch

|

74 lbs (33.6 kg)

|

|

S36C

|

36 inch (91.4 cm)

|

2 inch

|

103 lbs (46.8 kg)

|

|

S48CB

|

48 inch (121.9 cm)

|

2 inch

|

131 lbs (59.5 kg)

|

|

Combo

|

|

SCI48

|

48 inch (121.9 cm) (of Slitter)

|

2 inch

|

265 lbs (120.5 kg)

|

|

Perf Combo

|

|

SCI24HD

|

24 inch (61.0 cm) (of Slitter)

|

2 inch

|

188 lbs (85.5 kg)

|

Note: accessories may be incompatible with older Van-Mark products.

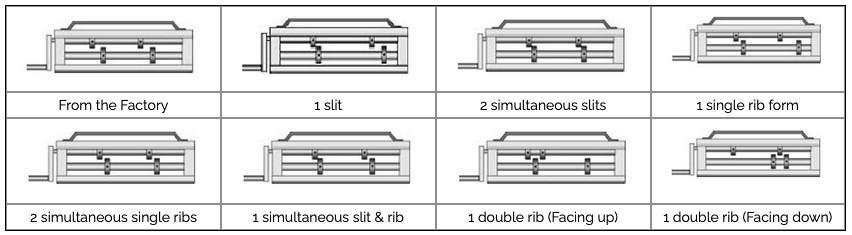

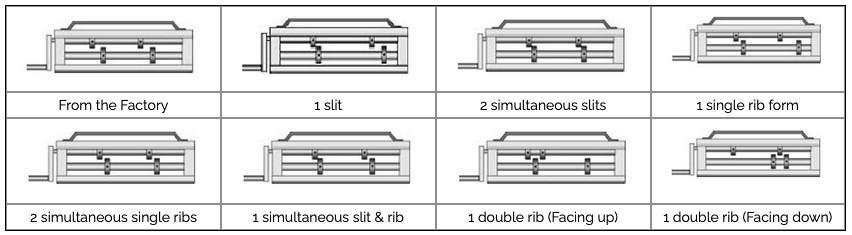

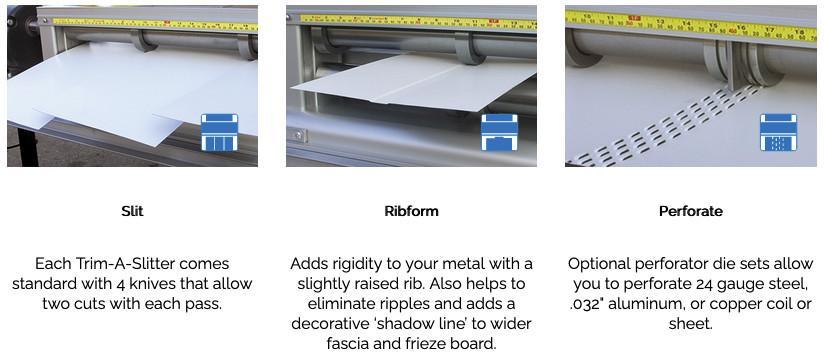

- Additional slitter knives may be added to any Trim-A-Slitter to increase productivity when slitting or ribforming.

- Manual operation allows use of slitter without a power source. Optional motor available in regular and heavy duty models to help increase production.

- 2 knives are required for each additional cut and 3 knives are required for each additional rib.

-

(please contact the factory for assistance on capacities when adding additional knives for slitting, ribforming, or perforating.)

|

Slitter Motor Kits

|

|

Motor No

|

USe

|

Motor

|

|

3521

|

Standard motor fits all slitter models.

|

115V, Single ph, 60 Hz, 32 Ft / Min

|

|

3522

|

For all slitters where 50 HZ is required.

|

230V, Single ph, 50 Hz, 26 Ft / Min

|

|

3535

|

Heavy-duty use for all slitters. Required when perforating steel.

|

115V, Single ph, 60 Hz, 35 Ft / Min

|

|

3533

|

Heavy-duty use for all slitters. Required when perforating steel. For all slitters where 50 HZ is required.

|

230V, Single ph, 50 Hz, 35 Ft / Min

|

Note: All motor kits come complete with coupling and mounting hardware.

|

Slitter Add-Ons and Accessories

|

|

Part No

|

Name

|

Uses

|

Slitters / Arbor Sizes

|

Packaged

|

|

5034

|

Slitter Knife

|

2 required (1 upper and 1 lower) per each additional cut. 3 required for each additional rib.

|

All B model slitters with 1.5 inch arbors

|

1 each

|

|

|

Slitter Knife

|

2 required (1 upper and 1 lower) per each additional cut.

3 required for each additional rib.

|

All C model slitters with 2 inch arbors

|

1 each

|

|

3007

|

Perforator Die Set

|

For perforating most light to medium construction grade materials. Provides 3.36 inches of net free area per foot running foot.

|

All B model slitters with 1.5 inch arbors

|

1 Male

1 Female

|

|

|

Perforator Die Set

|

For perforating most light to medium construction grade materials. Provides 3.36 inches of net free area per running foot

|

All C model slitters with 2 inch arbors

|

1 Male

1 Female

|

|

|

Stripper

|

Installs with perforators to prevent materials from winding on rolls.

|

All slitters and perforator sets

|

1 each

|

|

3578

|

Booster Block

|

(2) Recommended. Provides support under arbors to increase slitting capacity on 48 inch, 60 inch, and 72 inch slitters.

|

All C model slitters with 2 inch arbor shafts

|

1 each

|

|

|

Capacity Booster

|

Helps prevents arbors from spreading during slitting operation. Installs in conjunction with 1 set of slitting knives

|

All C model slitters with 2 inch arbor shafts.

|

1 each

|

|

|

|

|

|

Slitter shown with optional HD motor kit and perforator rolls.

|

All Van Mark Brakes, Tools and Accessories are

Manufactured AND Assembled in the USA!

Click Here to Download

Increase your productivity onsite or in your shop. The Trim-A-Slitter from Van Mark is designed to slit or stiffen aluminum, steel vinyl, or other materials, coil or sheet, quickly and accurately.

Helps to increase longevity of your brake by eliminating the practice of scoring the aluminum, which can damage the bending hinge by repeated use, when using a utility knife. Available in 14 inch,

24 inch, 36 inch, and 48 inch heavy duty models. There is a size for any particular cutting demand. Contact Van Mark today to find out how the Trim-A-Slitter will increase both your productivity

and your profits. We invite you to contact our sales professionals of your local distributor today to assist you with capacities and capabilities of any slitter and to help you find a productive

solution to meet your needs.

Features:

- Hardened steel, double sided slitting knives for long trouble-free service life.

- Precision ground Polished knives provides clean burr-free edges in all types of material.

- Anodized aluminum construction stands up to the rigors of all job site weather conditions.

- Easy to set up and use knives for slitting, rib forming, and optional perforators reposition in seconds.

- Slitter knives are easy to configure and can be disassembled to add an optinal perforator die set or additionl knives to meet your changing needs.

- Folding feed table with roller guides quickly adjusts to different widths of material.

- We offer a range of optional motors in standard and heavy duty. Suitable for multiple slits, ribs, or perforating a wide range of materials. Also available in both 110v and 220v single phase

for international voltages.

- Brass tipped set screws - Soft brass tips ensure secure position of slitting knives without damage to knives and arbor shaft.

- Optional perforating die set perforates steel, aluminum, zinc, and copper by producing a lanced perforation allowing 3.3 inch² of net free area, per running foot of metal.

- Additional accessories such as extra knives for multiple slites, rib forming, perforators, capacity boosters, and booster blocks are available, sold seperately.

Note: accessories may be incompatible with older Van-Mark products.

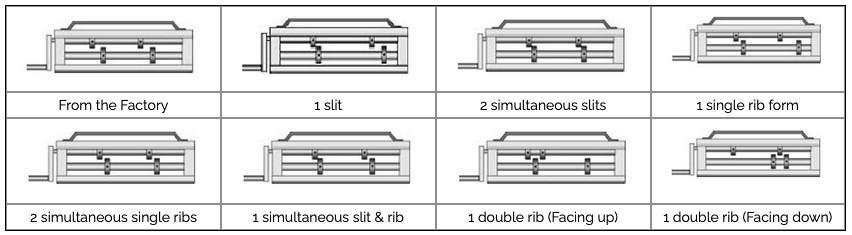

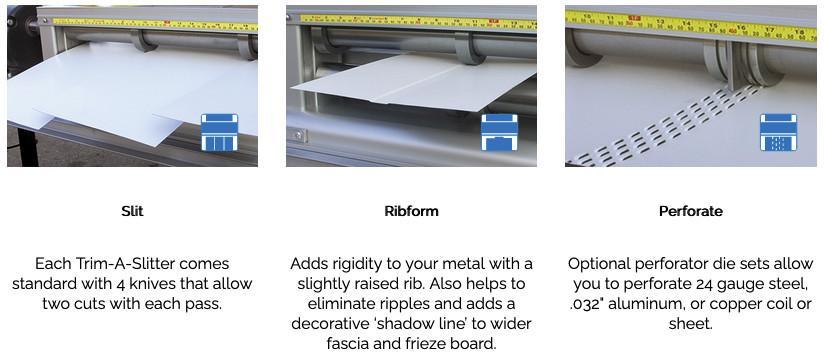

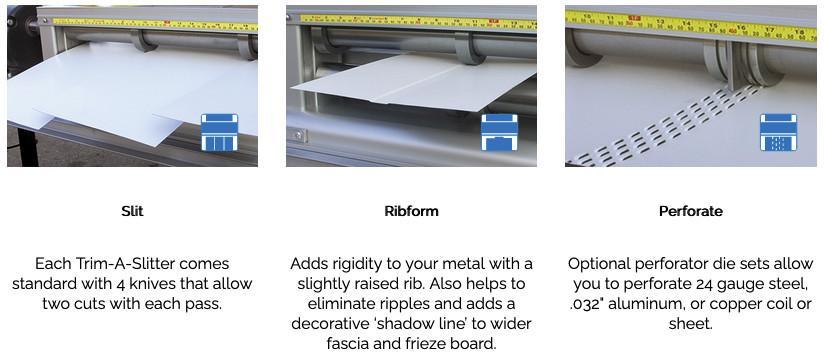

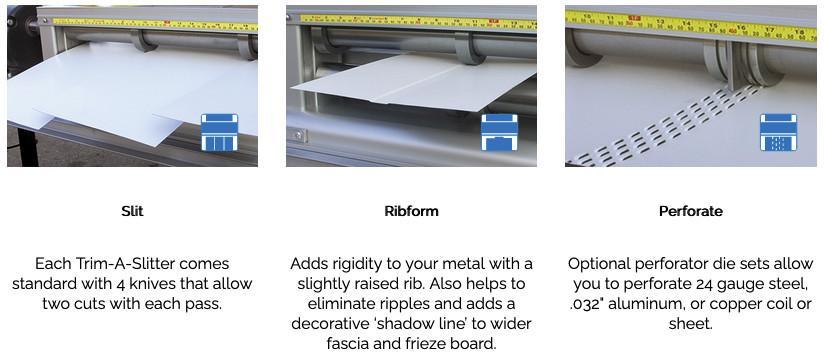

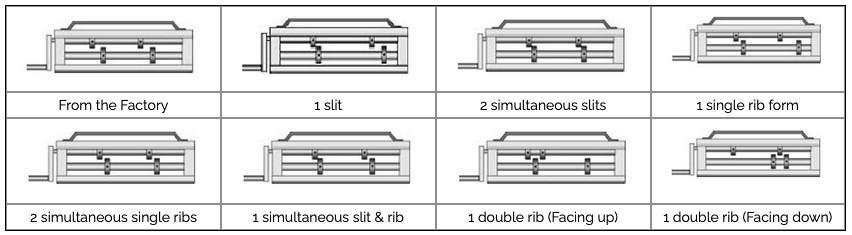

Slitter Configuration

|

Core Specs

|

|

Model

|

Length

|

Arbor

|

Weight

|

|

S14B

|

14 inch (35.5 cm)

|

1.5 inch

|

36 lbs (16.4 kg)

|

|

S24B

|

24 inch (61.0 cm)

|

1.5 inch

|

56 lbs (25.5 kg)

|

|

S24C

|

24 inch (61.0 cm)

|

2 inch

|

74 lbs (33.6 kg)

|

|

S36C

|

36 inch (91.4 cm)

|

2 inch

|

103 lbs (46.8 kg)

|

S48CB

Includes Booster Blocks (2 ea.)

|

48 inch (121.9 cm)

|

2 inch

|

131 lbs (59.5 kg)

|

|

Material Maximum Thickness

|

|

Aluminum (3003H14)

|

.040 inch (1.0 mm) slitting, .032 inch (0.8 mm) perforating

|

|

Galvanized Steel

|

24 ga. (0.6 mm)

|

|

Painted Steel (Grade D)

|

24 ga. (0.6 mm)

|

|

Roofing Copper

|

24 oz.

|

|

Zinc

|

.040 inch (1.0 mm)

|

|

Stainless Steel (304L)

|

Please call for capacities

|

|

Capacities are based on standard metal properties for coil and sheet. Please contact our representitive for capacities on your specific material

|

|

All Van Mark Brakes, Tools and Accessories are

Manufactured AND Assembled in the USA!

Click Here to Download

Forget the need to use your time consuming snips, shears, or nibblers to cut down your metals. The Industrial Trim-A-Slitter Combo quickly and easily slits your master coils or sheets to

the desired width, leaving a clean, burr free factory edge. Slitting knives adjust in seconds. The Industrial Trim-A-Slitter Combo is nearly turnkey ready to set up onsite or in your metal

shop and can be disassembled for easy transport and storage in minutes.

|

Features:

- Hardened steel, double sided slitting knives for long trouble-free service life.

- Precision ground and Polished knives provides clean burr-free edges in all types of material.

- Anodized aluminum construction stands up to the rigors of all job site weather conditions.

- Easy to set up and use knives for slitting, rib forming, and optional perforators reposition in seconds.

- Slitter knives are easy to configure and can be disassembled to add an optinal perforator die set or additionl knives to meet your changing needs.

- Folding feed table with roller guides quickly adjusts to different widths of material.

- The Built-In Tape Rule helps maintain slitter knife orientation with material.

- Can be ordered with an optional heavy duty motor and also standard and heavy duty motors for 220volt operation.

- Brass tipped set screws - Soft brass tips ensure secure position of slitting knives without damage to knives and arbor shaft.

- The perforating die set perforates steel, aluminum, zinc, and copper by producing a lanced perforation allowing 3.3 inch of net free area, per running foot of metal.

- Additional accessories such as extra knives for multiple slites, rib forming, perforators, capacity boosters, and booster blocks are available, sold seperately.

Note: accessories may be incompatible with older Van-Mark products.

Slitter Configuration

|

Core Specs

|

|

Model

|

Length

|

Arbor

|

Weight

|

|

SCI48

|

48 inch (121.9 cm) (of Slitter)

|

2 inch

|

265 lbs (120.5 kg)

|

|

Material Maximum Thickness

|

|

Aluminum (3003H14)

|

.040 inch (1.0 mm) slitting, .032 inch (0.8 mm) perforating

|

|

Galvanized Steel

|

24 ga. (0.6 mm)

|

|

Painted Steel (Grade D)

|

24 ga. (0.6 mm)

|

|

Roofing Copper

|

24 oz.

|

|

Zinc

|

.040 inch (1.0 mm)

|

|

Stainless Steel (304L)

|

Please call for capacities

|

|

Capacities are based on standard metal properties for coil and sheet. Please contact our representitive for capacities on your specific material

|

|

All Van Mark Brakes, Tools and Accessories are

Manufactured AND Assembled in the USA!

Click Here to Download

The Trim-A-Slitter Perf Combo from Van Mark is designed to slit, stiffen or perforate your roofing steel, aluminum, zinc and copper. Perforate 24 gauge painted steel onsite! Reduce your

material costs by producing your own perforated z-bar, ventilated soffit or ridge cap. Contact Van Mark today to find out how the Trim-A-Slitter 24 inch perforating combo will increase both

your productivity and your profits.

|

Features:

- Hardened steel, double sided slitting knives for long trouble-free service life.

- Precision ground and Polished knives provides clean burr-free edges in all types of material.

- Anodized aluminum construction stands up to the rigors of all job site weather conditions.

- Easy to set up and use knives for slitting, rib forming, and optional perforators reposition in seconds.

- Slitter knives are easy to configure and can be disassembled to add an optional perforator die set or additional knives to meet your changing needs.

- Folding feed table with roller guides quickly adjusts to different widths of material.

- The Built-In Tape Rule helps maintain slitter knife orientation with material.

- Heavy Duty, High Torque 110v reversible motor comes complete with motor mounted on/off switch.

- Brass tipped set screws - Soft brass tips ensure secure position of slitting knives without damage to knives and arbor shaft.

- The perforating die set perforates steel, aluminum, zinc, and copper by producing a lanced perforation allowing 3.3 inch of net free area, per running foot of metal.

- Optional foot pedal frees up an additional hand for handling of metal in and out of the slitter/perforator.

- Additional accessories such as extra knives for multiple slites, rib forming, perforators, capacity boosters, and booster blocks are available, sold seperately.

Note: accessories may be incompatible with older Van-Mark products.

Slitter Configuration

|

Core Specs

|

|

Model

|

Length

|

Arbor

|

Weight

|

|

SCI24HD

|

24 inch (61.0 cm) (of Slitter)

|

2 inch

|

188 lbs (85.5 kg)

|

|

Material Maximum Thickness

|

|

Aluminum (3003H14)

|

.040 inch (1.0 mm) slitting, .032 inch (0.8 mm) perforating

|

|

Galvanized Steel

|

24 ga. (0.6 mm)

|

|

Painted Steel (Grade D)

|

24 ga. (0.6 mm)

|

|

Roofing Copper

|

24 oz.

|

|

Zinc

|

.040 inch (1.0 mm)

|

|

Stainless Steel (304L)

|

Please call for capacities

|

|

Capacities are based on standard metal properties for coil and sheet. Please contact our representitive for capacities on your specific material

|

- Additional slitter knives may be added to any Trim-A-Slitter to increase productivity when slitting or ribforming.

- Manual operation allows use of slitter without a power source. Optional motor available in regular and heavy duty models to help increase production.

- 2 knives are required for each additional cut and 3 knives are required for each additional rib.

-

(please contact the factory for assistance on capacities when adding additional knives for slitting, ribforming, or perforating.)

|

Slitter Motor Kits

|

|

Motor No / USe

|

Motor

|

|

3521 Standard motor fits all slitter models.

|

115V, Single ph, 60 Hz, 32 Ft / Min

|

|

3522 For all slitters where 50 HZ is required.

|

230V, Single ph, 50 Hz, 26 Ft / Min

|

|

3535 Heavy-duty use for all slitters. Required when perforating steel.

|

115V, Single ph, 60 Hz, 35 Ft / Min

|

|

3533 Heavy-duty use for all slitters. Required when perforating steel. For all slitters where 50 HZ is required.

|

230V, Single ph, 50 Hz, 35 Ft / Min

|

Note: All motor kits come complete with coupling and mounting hardware.

|

Slitter Add-Ons and Accessories

|

|

Part No / Name

|

Uses

|

Slitters / Arbor Sizes

|

Packaged

|

|

5034 Slitter Knife

|

2 required (1 upper and 1 lower) per each additional cut. 3 required for each additional rib.

|

All B model slitters with 1.5 inch arbors

|

1 each

|

|

5035

Slitter Knife

|

2 required (1 upper and 1 lower) per each additional cut.

3 required for each additional rib.

|

All C model slitters with 2 inch arbors

|

1 each

|

3007

Perforator Die Set

|

For perforating most light to medium construction grade materials. Provides 3.36 inches of net free area per foot running foot.

|

All B model slitters with 1.5 inch arbors

|

1 Male

1 Female

|

|

3024A

Perforator Die Set

|

For perforating most light to medium construction grade materials. Provides 3.36 inches of net free area per running foot

|

All C model slitters with 2 inch arbors

|

1 Male

1 Female

|

|

5119

Stripper

|

Installs with perforators to prevent materials from winding on rolls.

|

All slitters and perforator sets

|

1 each

|

3578

Booster Block

|

(2) Recommended. Provides support under arbors to increase slitting capacity on 48 inch, 60 inch, and 72 inch slitters.

|

All C model slitters with 2 inch arbor shafts

|

1 each

|

|

3582

Capacity Booster

|

Helps prevents arbors from spreading during slitting operation. Installs in conjunction with 1 set of slitting knives

|

All C model slitters with 2 inch arbor shafts.

|

1 each

|