From the POWERslot hinge design, to the new hollow-core extrusions, Mark II TrimMaster answers the demand for quality and long service life. Discover the time and

money saving features designed into every Van Mark product for yourself.

-

POWERslot -New technology adds more bending power without sacrificing capacities.

-

Quick Hemming - Easily makes 180 degree over bends

-

Built-In-Tape Rule- Standard/Metric scale takes the guess work out of your bending routine.

-

Large Working Pocket- For complex custom bends without brake interference.

-

Vinyl Strips-Does not mar metal finishes while providing cushioned contact during bends.

-

Still Adjustable - You may never have to adjust your brake, but if you want to, that option is up to you!

-

Full Loop Handle - Ergonomic and Easy to grab, ensures even bending. Detaches quickly for transport.

Contractor Model - Building upon the reputation of the Mark I Series, the Mark II TrimMaster arrives with leading technologies such as the POWERslot,

easier bending, making smaller J channels and hollow core hinge extrusions for added strength. Weâââ‰â¢ve also left you the ability to make fine-tune adjustments to this brake, though you may

never have to. Ultra High Molecular Weight (UHMW), wedges are independently adjustable and replaceable should the occasion ever arise. After all, we believe a Van Mark brake is the closest thing to

a non-adjustment brake you'll find out there.

Note: accessories may be incompatible with older Van-Mark products.

Note : The difference between the Contractor & Commercial Grade Van Mark Brakes is that the Commercial Brakes have more C Brackets therefore making the Commercial Models a more Heavy Duty unit

for extreme work environments

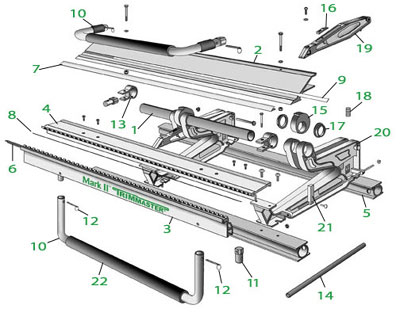

SETUP Click parts image for reference to numbers seen below in parenthesis.

-

The Locking Handle has extra bumper grips. Attach it (No. 10) to Handle Post (No. 11) with Fast Pins (No. 12).

-

Attach Bending Handle (also No. 10 without extra grips), to Handle Post (No. 11) with Fast Pins (No. 12).

MAINTENANCE

-

Protect working edges and surfaces from scratches, nicks or gouges.

-

Periodically tighten screws and nuts.

-

Keep bottom of F-Bar (No. 2) and top of Rear Hinge (No. 4) clean. This is where material is held for bending. This cleaning operation takes only a few seconds and

should be done at least once a day.

TRANSPORTING

-

When transporting brake, keep it unlocked and open or insert cardboard or another type of cushioning material between F-Bar (No. 2) and Rear Hinge (No. 4). This

will prevent abrasion and marks, which could transfer to material.

-

During all stages of use and transportation, ensure your brake is level and evenly supported to prevent warping

ADJUSTMENT

Note: Your brake has been pre-adjusted at the Factory and comes ready for service. Should you want to Fine-Tune your machine at some point in time, follow these steps.

-

Cut scrap siding or aluminum coil stock into approximately 2â square test pieces. All test pieces must be of the same thickness and one piece is required for each

Casting (No. 20)

-

Unlock brake by pulling Lock Handle (No. 10) toward operator.

-

Insert one inch of the test piece into the brake at each Casting and lock brake.

-

Note: Brake is properly locked when flat surface of Locking Cam (No. 15) is at rest against slope of Nylon

-

Wedge (No. 16), located on top of Pivot Arm (No. 19).

-

Try to pull each test piece straight out and determine through feel whether each piece is held with equal pressure.

-

If you can pull a test piece out, that Casting requires adjustment (see next step).

CASTING ADJUSTMENT:

Unlock brake, loosen screw that secures Wedge to Pivot Arm and slide Wedge towards back of brake in 1/8â increments until desired locking pressure is achieved. Re-test, follow steps 2-4. If Wedges

are worn and adjustments cannot be obtained, replace all Wedges with one (1) Replacement Wedge Kit #3900 for Contractor Models, or two (2) Kits #3900 for Commercial Models. If brake is properly

adjusted and material continues to slip, material is beyond the brake capacity. Switch to a thinner material, different alloy, or different temper.

BRAKE OPERATION

Techniques and examples shown herein are meant as basic guidelines as each job, or product can vary. We recommend practicing making bends with scrap metal until satisfied with the results.

MAKING BASIC SHAPES

-

Mark both ends of material to be bent (use pencil, punch or snips).

-

Insert material in brake to marks, lock brake by pushing Lock Handle (No. 10) all the way to the stop position.

-

Bend to desired angle in one continuous, smooth motion.

NOTE: During bend, hold Bending Handle equal distance from ends of Handle. If over bend on one end occurs while standing at center of brake, move your body in

opposite direction of over bend.