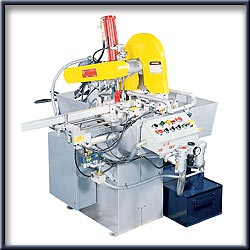

Metal Cutting Saws: 16" Fully Automatic Cutoff Saw

Complete with 7.5 or 10 HP TEFC motor, magnetic starter with 110 volt at the pushbuttons, fully automatic bar feed and air operated vise, Stock Roller Guides, Hardened Wear Pads,

Port Speed Control Mufflers.

Capacity: Aluminum 2" solidsââ¬â3" x 4" Extrusions

Steel 0.25" solidsââ¬â1.5" tubing or shapes

Call 1-800-458-3687 for pricing and availability.

Metal Cutting Saws: 16" Fully Automatic Cutoff Saw

Complete with 7.5 or 10 HP TEFC motor, magnetic starter with 110 volt at the pushbuttons, fully automatic bar feed and air operated vise, Stock

Roller Guides, Hardened Wear Pads, Port Speed Control Mufflers.

Capacity: Aluminum 2" solidsââ¬â3" x 4" Extrusions

Steel 0.25" solidsââ¬â1.5" tubing or shapes

-

Fully Automatic Bar Feed: Custom air feed is entirely pneumatic

and operates as smoothly and quietly as possibleââ¬âeasy feed length adjustment.

-

Low Maintenance: Due to fewer moving parts; standard off the shelf hardware used wherever possible.

-

Feed Block: Slides on hardened and ground rods with linear ball bearings.

-

Cool Running: 10 GPM coolant system: 21 gallon reservoir

-

High Speed: High production cutting up to 2000 cycles/hr cutting 1/2 x 1/2 x 1/2 aluminum

-

Hydraulic Shock Absorber: For higher feed rates and long life

-

Flexible: Cuts most materialââ¬âaluminum, copper, brass, plastic and small sizes of mild steel, tool steel and stainless steel

-

Cut Most Shapes: From extrusions to die pins and punches, interchangeable steel blades and abrasive

wheels

Abrasive Wheels: Dry Reinforced Abrasive Cutting Wheels

Link for Everett Dry Cut Abrasive Blades

All the cutting wheel grades have been developed and extensively tested to produce quality

cuts on a wide range of material alloys, sizes and shapes.

As a manufacturer of abrasive wheels, we have other grades of wet and dry abrasive wheels to meet your specific requirements. Contact us for special diameter, thickness, arbor hole and drive pin

requirements of abrasive wheels.

Fiberglass Internally Reinforced Resinoid Bond Aluminum Oxide Cutting Wheels

Woven fiberglass cloth is molded in the center of the abrasive wheel for break resistance.

|

Grade

|

|

Description of Cutting Wheels

|

|

|

45FG

|

|

For general purpose cutting

|

|

|

|

|

|

|

|

23020FG

|

|

Designed for use on machines with POWERHEAD (automatic wheel feed) where free cutting ability is needed because of constant feed pressure

|

|

|

|

|

|

|

|

2069FG

|

|

Ideal for heavier wall shapes and tubing

|

|

|

|

|

|

|

|

T32 FG

|

|

For cutting thin wall shapes and thin wall tubing

|

|

|

|

|

|

|

|

GTK-7FG

|

|

Excellent for high quality dry cuts on stainless tubing and other thin wall tubing

|

|

Fiberglass Externally Reinforced Cutting Wheels

Woven fiberglass cloth is applied externally on both sides of the abrasive wheel for break resistance.

|

Grade

|

|

Description of Cutting Wheels

|

|

|

45FGE

|

|

For general purpose cutting

|

|

|

|

|

|

|

|

23020FGE

|

|

Designed for use on cutoff saws with POWERHEAD (automatic

wheel feed) where free cutting ability is needed because of constant feed pressure

|

|

|

|

|

|

|

|

2069FGE

|

|

Ideal for heavier wall shapes and tubing

|

|

|

|

|

|

|

|

T32 FGE

|

|

For cutting thin wall shapes and thin wall tubing

|

|

|

|

|

|

|

|

GTK-7FGE

|

|

Excellent for high quality dry cuts on stainless tubing and other thin wall tubing

|